For e-commerce businesses, it’s vital to make sure products are being stored and fulfilled quickly and efficiently.

- Over 60% of shoppers abandon carts if shipping, taxes, and other fees are too high.

- Poor delivery experience results in 38% of shoppers looking elsewhere the next time they select a retailer.

- 53% of shoppers report speed of delivery as an important factor for online orders.

- A slow delivery speed results in a quarter of all shoppers backing out of an order.

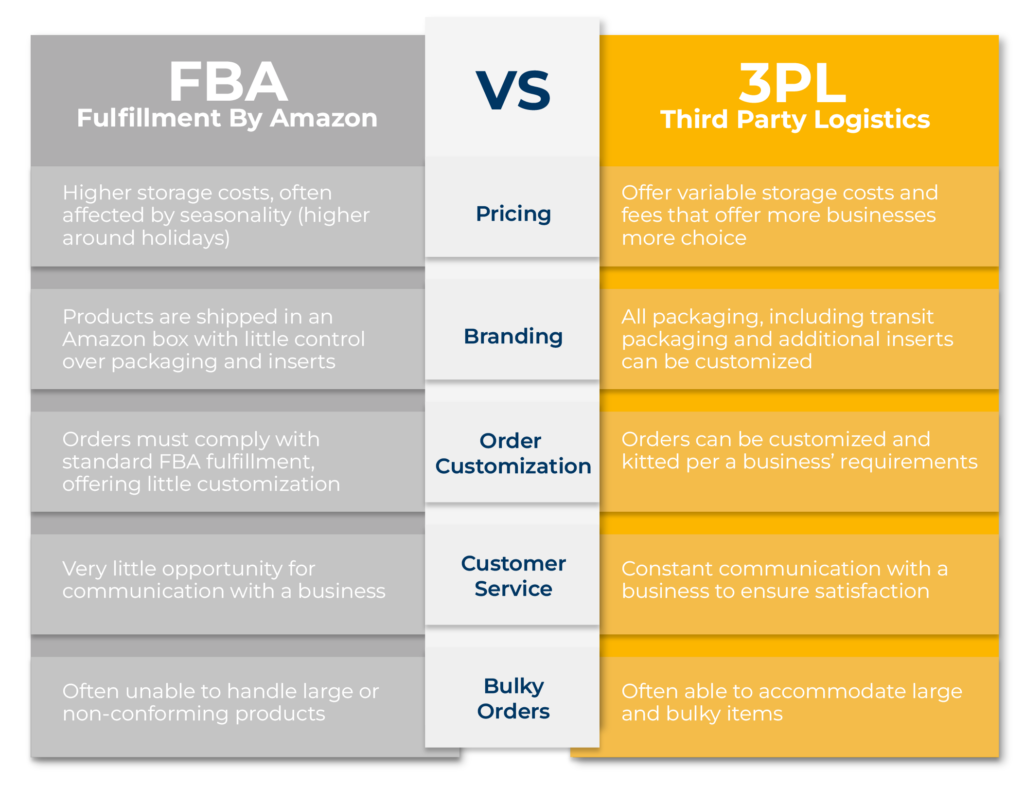

There are several ways to fill orders: a company can choose to do fulfillment in-house, by partnering with a third-party fulfillment service, or by dropshipping. When you outsource fulfillment to a 3PL company, they handle the entire fulfillment process for you — from receiving your inventory from your manufacturer to restocking returned products. Fulfillment by Amazon (FBA) is a popular option for outsourcing fulfillment but isn’t the best choice for every business. Let’s take a deeper look at the FBA fulfillment option, and when a business should choose it vs an independent 3PL.

Why You Should Choose a 3PL Over Amazon FBA

When it comes to eCommerce fulfillment, businesses often find themselves deciding between third-party logistics (3PL) providers and Amazon’s Fulfillment by Amazon (FBA) service. While FBA offers convenience, a 3PL can provide more flexibility, cost savings, and brand control. Here’s why choosing a 3PL over Amazon FBA may be the smarter choice for your business.

Cost Savings and Fee Transparency

Amazon FBA comes with numerous fees, including storage fees, fulfillment fees, and additional charges for long-term storage and peak season surcharges. These costs can add up quickly, making it challenging to maintain profitability, especially for businesses with lower margins.

3PL providers, on the other hand, offer more transparent pricing structures. Many 3PLs allow businesses to negotiate contracts, ensuring fulfillment costs align with business needs without excessive add-on fees. This cost predictability can help businesses scale more efficiently.

FBA Inventory Fees and Restrictions

Amazon has implemented an inventory performance index (IPI) to track inventory levels and optimization. If a business is unable to keep its IPI above the minimum threshold, it will be subject to inventory storage restrictions and higher storage fees. In addition, FBA imposes long-term storage fees on products that take longer than 180 days.

Breakdown of Amazon FBA Fees

1. Fulfillment Fees – Charged per unit, these fees depend on the size and weight of each product. They cover picking, packing, and shipping but can be costly for oversized or heavy items.

Amazon’s Fulfillment by Amazon (FBA) program structures its fulfillment fees based on the size and weight of each product. Consider a standard-size non-apparel item weighing 1 lb. As of January 15, 2025, the fulfillment fee for such an item is $3.22. Source: sellersnap.io

2. Storage Fees – Monthly storage fees are based on the volume of inventory stored in Amazon’s warehouses. Prices increase during peak seasons, particularly from October to December.

Amazon’s Fulfillment by Amazon (FBA) program charges monthly storage fees based on the volume of inventory stored in its fulfillment centers. These fees are calculated per cubic foot and vary depending on the time of year and the size of the product.

Standard-Size Products:

- January – September: $0.78 per cubic foot

- October – December: $2.40 per cubic foot

Oversize Products:

- January – September: $0.53 per cubic foot

- October – December: $1.40 per cubic foot

Note: These rates reflect a reduction during the non-peak period (January through September) for standard-size products, decreasing from $0.87 to $0.78 per cubic foot.Source: goatconsulting.com

Example Calculation:

If you have a standard-size product occupying 2 cubic feet of space:

- January – September: 2 cubic feet × $0.78 = $1.56 per month

- October – December: 2 cubic feet × $2.40 = $4.80 per month

These fees underscore the importance of efficient inventory management, especially during peak seasons, to minimize storage costs.

3. Long-Term Storage Fees – Inventory stored in Amazon fulfillment centers for more than 365 days incurs an additional surcharge, making it expensive for slow-moving products.

Amazon’s Fulfillment by Amazon (FBA) program imposes long-term storage fees on inventory that remains in their fulfillment centers for extended periods. As of 2025, these fees apply to items stored for more than 365 days and are calculated as follows:

Fee Structure: $6.90 per cubic foot/month or $0.15 per unit/month, whichever is greater. Source: shipbob.com

Example Calculation:

Consider you have 100 units of a product that have been in storage for over a year, occupying a total of 10 cubic feet.

- Cubic Foot Calculation: 10 cubic feet × $6.90 = $69.00

- Per Unit Calculation: 100 units × $0.15 = $15.00

In this scenario, the long-term storage fee would be $69.00, as it is the greater amount.

These fees are in addition to the standard monthly storage fees and can significantly impact profitability, especially for slow-moving products. Effective inventory management is crucial to minimize these costs. Source: marketplacevalet.com

4. Peak Season Surcharges – Amazon increases fees during high-demand periods, which can further strain profit margins.

Amazon’s Fulfillment by Amazon (FBA) program has historically implemented peak season surcharges during high-demand periods, typically from October to January. These surcharges are applied to fulfillment fees and storage costs to account for increased operational demands.

Fulfillment Fees: During peak seasons, Amazon increases fulfillment fees to manage the heightened demand. For instance, in previous years, standard-size items faced an additional surcharge per unit during the peak period. However, as of January 15, 2025, Amazon announced that peak fulfillment fees would end, and non-peak rates would apply moving forward. Source: sellersnap.io

Storage Fees: Storage fees also see an uptick during peak seasons. For example, from October through December, monthly storage fees for standard-size items have increased from $0.87 to $2.40 per cubic foot in previous years. This significant rise reflects the premium on warehouse space during the holiday rush. Source: goatconsulting.com

Example Calculation: Consider a seller storing 500 standard-size units occupying 50 cubic feet of space during the peak season:

- Non-Peak Storage Cost (January – September): 50 cubic feet × $0.87 = $43.50 per month

- Peak Storage Cost (October – December): 50 cubic feet × $2.40 = $120.00 per month

In this scenario, the seller would incur an additional $76.50 per month during the peak season due to increased storage fees.

It’s essential for sellers to stay updated on Amazon’s fee announcements, as these charges can significantly impact profitability during peak periods. Planning inventory levels and fulfillment strategies accordingly can help mitigate the financial impact of these surcharges.

5. Removal and Disposal Fees – If a seller wants to remove or dispose of inventory from Amazon warehouses, additional fees are charged per unit, which can add up quickly.

Amazon’s Fulfillment by Amazon (FBA) service offers sellers the option to remove or dispose of inventory stored in its fulfillment centers. These services incur fees that vary based on the size and weight of the items. As of 2025, Amazon charges the following fees for both removal (returning items to the seller) and disposal (destroying or liquidating items):

- Standard-Size Items:

- 0 to 0.5 lb: $1.04 per unit

- 0.5+ to 1 lb: $1.50 per unit

- 1+ to 2 lb: $2.15 per unit

- Over 2 lb: $2.15 + $0.88 per additional lb above 2 lb

- Oversize Items:

- 0 to 1 lb: $2.15 per unit

- 1+ to 2 lb: $3.31 per unit

- 2+ to 3 lb: $4.68 per unit

- Over 3 lb: $4.68 + $0.88 per additional lb above 3 lb

Example: If a seller needs to remove 100 standard-size units, each weighing 1.5 pounds, the removal fee would be calculated as follows:

- Per Unit Fee: $2.15

- Total Fee: $2.15 x 100 units = $215

It’s important to note that these fees can add up quickly, especially for large quantities or heavier items. Sellers have reported significant charges upon initiating removal orders. Source: sellercentral.amazon.com

6. Returns Processing Fees – While Amazon manages returns, sellers often bear the cost of returns processing, which varies by product category.

As of June 1, 2024, Amazon implemented a returns processing fee for products with high return rates across most categories, excluding apparel and shoes. This fee is calculated based on the product’s monthly return rate, category, size, and weight. The return rate is determined by the percentage of shipped units in a given month that are returned over that month and the subsequent two calendar months. The returns processing fee is charged between the 7th and 15th of the third subsequent month. Source: ecomengine.com

For each return that exceeds the category’s threshold, sellers are charged a per-unit fee ranging from $1.78 to over $157.35, depending on the product’s size and weight. Source: shipbob.com

Example: Consider a board game that falls under a category with a return rate threshold of 4.70%. If the product’s return rate exceeds this threshold, the returns processing fee for this product size tier is $1.84 per returned unit. Source: litcommerce.com

It’s important to note that for products shipping fewer than 25 units in a month, the returns processing fee is not applied for that month. Additionally, for products enrolled in the New Selection Program, Amazon waives the fee for the first 20 returned units that exceed the return rate threshold. Source: sellercentral.amazon.com

7. Referral Fees – Amazon takes a percentage of each sale, typically ranging from 8% to 15%, depending on the product category.

Amazon FBA charges Referral Fees for every item sold on the platform. The referral fee is a percentage of the total sales price (including shipping charges, if applicable) and varies depending on the product category. These fees are separate from fulfillment fees and are charged to the seller when a sale is made.

Referral Fee Structure: The Referral Fee is typically a percentage of the total sales price, but the percentage varies by product category. Below are some common categories and their associated referral fees:

- Clothing and Accessories: 17%

- Consumer Electronics: 8% to 15%, depending on the product’s price.

- Health & Personal Care: 15%

- Home & Kitchen: 15%

- Toys & Games: 15%

- Books (Physical): 15% (with a minimum fee of $1.00 per unit)

- Video Games & Consoles: 8% to 15%, depending on price.

- Jewelry: 20% for prices up to $250, and 5% for prices over $250.

- Sports & Outdoors: 15%

- Automotive: 12% to 15%

Minimum Referral Fee:

For some categories, Amazon charges a minimum referral fee, which ensures that the seller still pays a minimum amount regardless of how low the sale price is. For example:

- Books: A minimum fee of $1.00 per unit.

- Video Games: A minimum fee of $0.30 per unit.

Example of Referral Fees:

Let’s say you sell a product in the Home & Kitchen category with a sale price of $50.00:

- Referral Fee: 15% of $50.00 = $7.50.

If you sell a book priced at $12.00:

- Referral Fee: 15% of $12.00 = $1.80 (but if the minimum fee is higher, it would be $1.00).

For a consumer electronics product priced at $200.00:

- Referral Fee: 8% of $200.00 = $16.00.

8. Account-Related Fees – Professional selling plans, advertising costs, and other promotional expenses add to the overall cost structure.

Amazon FBA charges several account-related fees to sellers, depending on the type of account they have and the services they use. Here’s a breakdown of the typical account-related fees you might encounter as an Amazon seller:

Amazon Seller Account Subscription Fees

- Individual Seller Account: $0.99 per item sold.

- This is the fee for individual sellers who don’t have a professional account. There is no monthly subscription fee, but they pay $0.99 per sale made.

- Professional Seller Account: $39.99 per month (regardless of the number of items sold).

- This is for businesses or higher-volume sellers who want more features and don’t mind paying a monthly fee. Professional sellers also have access to Amazon’s advertising options, advanced analytics, and can list in more categories.

Amazon Payment Processing Fees

- Amazon charges payment processing fees for each sale made on the platform. These fees are generally taken out of the proceeds before funds are disbursed to the seller.

- The fee is typically 2.9% + $0.30 per transaction for most U.S. sales.

- If the sale is made in a different currency or region, Amazon adjusts the processing fees accordingly.

Amazon FBA Inventory Removal Fees

- When sellers want to remove their unsold inventory from Amazon’s fulfillment centers, there’s a fee for removing products:

- Removal Fee: $0.15 per unit for standard-size items, $0.30 per unit for oversized items.

- This fee covers the cost of retrieving and returning the item to you (if it’s sent back to you) or discarding it.

Long-Term Storage Fees

- Amazon charges long-term storage fees for inventory that has been in a fulfillment center for more than 365 days (one year).

- These fees are charged twice a year (in February and August) and are calculated based on the amount of space your inventory takes up.

- Standard-size items: $6.90 per cubic foot.

- Oversized items: $0.15 per unit per month or $3.45 per cubic foot (for long-term storage).

Refund Administration Fee

- If a customer returns a product and Amazon issues a refund, sellers typically pay a refund administration fee.

- Refund Administration Fee: $5.00 or 20% of the refunded amount (whichever is less).

- This is deducted from your Amazon account when the return is processed.

High-Volume Listing Fee

- For sellers with large numbers of listings, Amazon may charge a high-volume listing fee if the seller has over 100,000 active listings in Amazon’s catalog.

- Fee: This is typically charged on a per-listing basis and varies by region.

- This fee applies to sellers who maintain many listings but don’t have significant sales to match the listings.

Amazon Advertising Fees (Optional)

- While not required for all sellers, many opt into Amazon’s advertising services to help promote their products, which incurs additional costs.

- Sponsored Products: Advertisers pay based on a pay-per-click (PPC) model. Costs typically range from $0.10 to $2.00 per click, depending on the keywords and competition.

Account Maintenance Fees (for inactive accounts)

- If your seller account becomes inactive (i.e., no sales or listings) for a period of time, Amazon may charge an account maintenance fee to keep your account open and active.

Fee: It can be up to $10 per month if an account is inactive for more than 90 days.

3PL Cost Benefits

A specialized 3PL provider typically offers a more transparent pricing model with flexible fulfillment options. Here’s why businesses may find cost savings with a 3PL:

- Negotiable Storage Costs – Unlike Amazon, where storage costs are dictated by peak seasons and long-term surcharges, 3PL providers offer customizable storage solutions.

- Flexible Fulfillment Pricing – Many 3PLs charge based on service usage rather than per-unit fees, making it more cost-effective for businesses with diverse product sizes and shipping needs.

- No Referral Fees – Selling through Amazon FBA requires paying a referral fee on every sale, whereas a 3PL allows businesses to keep more of their revenue.

- Lower Returns and Handling Costs – Businesses using a 3PL can set their own return policies and manage returns more cost-effectively.

- Multi-Channel Support – With a 3PL, businesses can fulfill orders from multiple platforms (Shopify, Walmart, eBay, etc.) without being locked into Amazon’s ecosystem.

Ultimately, while FBA offers convenience, its cost structure can eat into profit margins, especially for businesses with slow-moving inventory or high storage needs. A specialized 3PL provider allows for greater control over costs, better scalability, and more predictable pricing, making it a compelling choice for long-term growth.

Greater Control Over Branding

Amazon FBA requires that all products be shipped in Amazon-branded packaging, limiting a business’s ability to build its own brand identity. Additionally, customer interactions are controlled by Amazon, making it harder to create a personalized experience for shoppers.

Amazon FBA and Branding Limitations

One of the main considerations for sellers using Amazon FBA is the lack of flexibility when it comes to branding. Here’s why:

- Amazon-Branded Packaging:

- FBA Requirements: When you use Amazon FBA, all products are shipped in Amazon-branded packaging. This means that customers will receive products with Amazon’s logos, labeling, and designs on the outer packaging.

- Impact on Branding: This is a significant limitation for businesses that want to create a unique unboxing experience or make a strong brand impression. Amazon’s packaging doesn’t allow you to include your company’s logos, colors, or any custom messages on the external packaging. The Amazon logo will typically dominate, leaving little room for your branding to shine.

- Inability to Include Custom Inserts: Amazon FBA also has restrictions on the types of promotional materials, inserts, or coupons that can be included in shipments. If you want to include a branded thank-you card, an instruction manual, or a promotional flyer, Amazon typically does not allow this unless it’s related to the product itself.

- Product Labeling Restrictions:

- Amazon’s labeling requirements are strict, and custom packaging for each item is usually prohibited. Sellers must follow specific guidelines for labeling, which often means their brand identity is limited to the product itself and not the packaging.

- Unboxing Experience:

- FBA Fulfillment Process: The process of shipping an item from Amazon’s warehouse involves limited interaction with the brand. The product is packed according to Amazon’s standards, which means sellers don’t have control over the unboxing experience.

- For brands looking to personalize the customer’s first interaction with the product, this can be a huge drawback. Customization like branded tissue paper, unique boxes, or luxury unboxing experiences won’t be possible with Amazon FBA.

Greater Branding Flexibility with 3PL Fulfillment

On the other hand, 3PL providers offer a much broader range of customization options to help businesses create unique, branded experiences for their customers. A 3PL allows businesses to use custom packaging, branded inserts, and unique unboxing experiences that reinforce brand identity. This enhances customer loyalty and improves retention rates.

Here are the key areas where 3PLs offer greater control over branding:

- Custom Packaging:

- Custom Branded Boxes: With 3PL fulfillment, businesses can work with their 3PL provider to design and order custom-branded boxes that feature their logo, brand colors, and unique design. This enables a cohesive brand presentation, from the moment the customer receives the package to the moment they open it.

- Custom Mailers & Polybags: For products that require packaging other than boxes, 3PLs can provide branded mailers, poly bags, or pouches. These can also be custom-printed with your logo, brand name, and colors, ensuring that every piece of packaging reinforces your brand identity.

- Sustainable Packaging: Many 3PLs also offer the option for eco-friendly or sustainable packaging, which can be a key element of a brand’s identity, particularly for environmentally conscious consumers. This includes biodegradable packing materials, recycled paper, and compostable mailers.

- Inserts & Custom Messages:

- Branded Inserts: A key advantage of using 3PL fulfillment is the ability to include custom inserts in your packages. These can be thank-you cards, discount coupons for future purchases, promotional materials, and even personalized notes for your customers. Inserts allow you to foster a connection with customers, encourage repeat business, and share special promotions.

- Exclusive Offers: By including promotional flyers, catalogs, or special offers, 3PLs enable brands to provide customers with exclusive deals that can increase customer loyalty. For example, a brand could add a personalized message offering 10% off the customer’s next purchase, driving engagement and repeat sales.

- Brand Story & Experience: You can also include items that promote the brand story, such as explaining the mission, values, or the company’s commitment to sustainability. A personalized unboxing experience will help build customer loyalty by creating a positive emotional connection with the brand.

- Luxury or Premium Unboxing Experiences:

- Packaging Design: If you’re selling premium or luxury products, 3PLs allow you to create high-end, custom packaging with elements like foiling, embossing, or magnetic closures. These features can elevate the unboxing experience, helping your brand stand out and make a lasting impression.

- Gift Wrapping: Some 3PLs even offer gift-wrapping services, which can be used for specific products or during the holiday season. This service lets customers send gifts with a beautifully wrapped box featuring your branding.

- Product Preparation & Custom Bundles:

- Custom Bundling: Many 3PLs allow you to bundle products together in custom configurations. For example, if you’re selling skincare products, you can bundle a set of products in a beautifully packaged box to create a unique offering. This kind of bundling can reinforce your brand’s value and attract customers who are looking for curated sets.

- Product Prep Services: If your product requires special preparation before shipping, such as assembling kits, adding labels, or sealing items in bags, a 3PL can handle these tasks with care and attention to your brand’s specific requirements. This level of customization is often essential for maintaining product quality and brand consistency.

- Personalized Shipping Labels & Branding:

- 3PLs also allow the use of personalized shipping labels with your business name and logo on them. This ensures that customers immediately recognize your brand when they receive their package. You can also include a branded tracking page with your logo when customers track their shipments.

- Customization at Scale:

- Flexibility for Large and Small Businesses: Whether you are shipping 100 units a month or 100,000, 3PL providers can scale their fulfillment services to meet your needs while maintaining a high level of branding consistency. This is ideal for businesses that want to maintain a personalized, branded experience as they grow.

- Multiple Fulfillment Centers: With 3PLs, you can choose fulfillment centers that are geographically closer to your customers, which can enhance the unboxing experience by reducing delivery times and offering more flexibility in packaging and customization.

Over 50% of online shoppers who received their products in a custom package say they are more likely to become returning customers.

Flexible Storage and Fulfillment Options

FBA has strict storage limits, particularly for new or lower-volume sellers, and penalizes businesses with high storage costs for slow-moving inventory. Amazon’s system prioritizes its own interests, sometimes limiting the ability of sellers to keep products available.

With a 3PL, businesses have more control over inventory management, including flexible warehousing solutions that adapt to seasonal demand. Many 3PLs also support multi-channel fulfillment, meaning businesses can sell through Amazon, Shopify, Walmart, and other platforms without being tied to Amazon’s ecosystem.

Amazon FBA’s Storage Limits and Penalties

While Amazon FBA provides a highly streamlined and well-established fulfillment service, it comes with some limitations in terms of storage capacity and inventory management, especially for businesses that are new to the platform or have lower sales volume. Here’s how FBA’s storage and fulfillment options work:

- Strict Storage Limits for New and Lower-Volume Sellers:

- Storage Limitations: Amazon imposes storage limits on FBA sellers, especially those with low sales volume or new accounts. The amount of storage space you are allotted in Amazon’s warehouses depends on a number of factors, including your sales history and inventory turnover. For example, new sellers or those with a small product range may be restricted to smaller storage quotas.

- Inventory Performance Index (IPI): Amazon uses the Inventory Performance Index (IPI) to evaluate how well you manage your inventory. If your IPI score is low (due to factors like overstocking or slow-moving inventory), Amazon may restrict your inventory storage even further. In extreme cases, Amazon can impose storage limits that prevent you from sending new inventory to its fulfillment centers until you improve your IPI score.

- Slow-Moving Inventory: Amazon has stringent policies regarding slow-moving inventory, and products that don’t sell quickly can result in hefty long-term storage fees. These fees are imposed for inventory stored for more than 365 days, making it costly for businesses that struggle with inventory turnover. The long-term storage fee is $6.90 per cubic foot for standard-size items, and even higher for oversized products. Sellers can be penalized with significant costs if they fail to manage their inventory effectively, leading to a deterioration of profit margins.

- Limited Control Over Inventory Location:

- When you use Amazon FBA, you have little to no control over where your inventory is stored. Amazon’s system places products in its fulfillment centers across the U.S. and internationally, based on its own internal algorithms. This lack of control can make it difficult for businesses to manage regional demand, as their inventory may not be optimized for the markets they are trying to serve.

- Penalty for Overstocking:

- Amazon also penalizes businesses that overstock. If you send too much inventory to their fulfillment centers, Amazon may charge additional storage fees or limit your ability to send more products in. This can put significant pressure on businesses to forecast demand accurately, particularly for seasonal or niche products.

3PL Fulfillment: Greater Flexibility in Storage and Fulfillment

Unlike Amazon FBA, 3PL providers offer more flexible storage and fulfillment options, giving businesses greater control over their inventory management, seasonal demand, and multi-channel sales. Here’s how 3PLs support businesses with their storage and fulfillment needs:

- Flexible Warehousing Solutions:

- Customizable Storage Options: Many 3PL providers offer flexible warehousing solutions, where you can choose the amount of space you need and scale it as your business grows. Whether you are a startup with fluctuating demand or an established business with seasonal spikes, 3PLs allow you to adjust storage space to meet the needs of your business.

- Seasonal Demand Flexibility: 3PLs are better equipped to handle seasonal demand. For example, if your business experiences significant spikes during the holidays, a 3PL can help you secure additional warehouse space to store seasonal products. This flexibility helps businesses avoid the high costs of long-term storage fees charged by Amazon FBA, as 3PLs typically allow you to scale storage capacity based on demand without imposing penalties for slow-moving inventory.

- Inventory Location Control: Unlike Amazon FBA, where Amazon determines where your products are stored, 3PLs allow you to choose where your inventory is placed. You can opt for warehouses that are closer to specific geographic regions or that better support your supply chain needs. For example, if you serve both the East Coast and West Coast markets, a 3PL can place inventory in warehouses located in both regions, helping you optimize shipping times and reduce costs.

- Multi-Channel Fulfillment (MCF):

- Selling Across Multiple Platforms: One of the key advantages of using a 3PL is the ability to sell through multiple channels. While Amazon FBA is primarily designed for sales within the Amazon marketplace, 3PLs allow businesses to sell across a variety of platforms, including:

- Amazon: With 3PLs, businesses can still sell on Amazon and fulfill orders through FBA, but they also have the flexibility to use their 3PL for inventory storage and fulfillment.

- Shopify: If you operate your own e-commerce website using Shopify, a 3PL can store and fulfill orders directly from your Shopify store, integrating seamlessly with your system.

- Walmart Marketplace: Many 3PLs also offer integration with Walmart Marketplace, allowing businesses to fulfill orders made on Walmart’s platform.

- Other Marketplaces: 3PLs can integrate with various other sales platforms, including eBay, Etsy, BigCommerce, Magento, and more. This means businesses can sell on multiple channels without being tied to Amazon’s ecosystem and have the option to fulfill orders from one central inventory pool.

- Unified Fulfillment Network: By leveraging a 3PL, you create a unified fulfillment network that can serve all of your sales channels. This is beneficial for businesses that want to reduce the complexity of managing separate fulfillment strategies for each platform.

- Selling Across Multiple Platforms: One of the key advantages of using a 3PL is the ability to sell through multiple channels. While Amazon FBA is primarily designed for sales within the Amazon marketplace, 3PLs allow businesses to sell across a variety of platforms, including:

- Inventory Management and Real-Time Data:

- Advanced Reporting and Analytics: Many 3PL providers offer advanced inventory management systems that provide real-time data and insights into your stock levels, sales velocity, and order history. This allows you to make more data-driven decisions about when and how to reorder stock, minimizing the risk of overstocking or understocking.

- Smarter Replenishment: With access to real-time inventory data, you can optimize stock levels across different fulfillment channels, ensuring that you’re not sending too much inventory to one warehouse or market. This also helps with better demand forecasting and efficient use of storage space, reducing the risk of overpaying for storage fees.

- No Penalties for Slow-Moving Inventory:

- Unlike Amazon FBA, where slow-moving inventory can result in costly long-term storage fees, 3PLs generally do not charge penalties for slow-moving stock. Instead, businesses can store inventory for as long as necessary without incurring additional fees. This provides flexibility for businesses with longer product life cycles or slower sales periods, helping to optimize working capital.

- Scalability:

- As your business grows, your storage and fulfillment needs may evolve. 3PL providers are highly scalable and can adjust to your changing needs. Whether you’re expanding internationally or increasing the volume of products you offer, a 3PL can grow alongside your business without the restrictions imposed by Amazon FBA’s rigid storage limits or performance metrics.

Better Customer Service and Returns Management

Amazon FBA manages returns, but its process can sometimes be unfavorable for sellers, with restocking fees and inconsistent return decisions. Additionally, FBA customer service interactions are handled by Amazon, which can result in disputes that are difficult for sellers to resolve.

A 3PL allows businesses to maintain better control over returns, implement flexible return policies, and offer direct customer service. This creates a better overall experience for buyers and can lead to higher customer satisfaction.

Amazon FBA Returns Management: Seller Disadvantages

- Restocking Fees and Other Costs:

- Restocking Fees: Amazon FBA charges a restocking fee of up to $15 or 20% of the item’s price (whichever is greater) for returns that are deemed to be in “good condition” and resellable. This means that if a customer returns a product, and Amazon decides it can be resold, the seller is hit with this restocking fee. However, Amazon has the discretion to determine the condition of the returned item, which can sometimes lead to unfair assessments. Sellers often have little recourse if Amazon decides to charge a restocking fee, even in cases where the item is returned in near-new condition or if there are issues with how the return was handled.

- Impact on Profit Margins: Restocking fees, along with potential shipping fees for returned items, can severely impact profit margins. These charges can be especially damaging for small businesses that may already be operating with thin margins. In some cases, businesses face higher fees for returns than they might have anticipated when originally setting the price for their product.

- Inconsistent Return Decisions:

- Amazon’s Return Policies: Amazon has a customer-first approach when it comes to returns, which often works in favor of the customer but not always in favor of the seller. Amazon allows customers to return items easily, and their return policy is typically quite lenient (e.g., 30 days for most products). However, the decision-making process for whether an item is returned as “damaged” or in “used condition” is solely at Amazon’s discretion, and sellers have very little say in this decision.

- Lack of Transparency: Many sellers report frustration with Amazon’s inconsistent return decisions. For instance, a customer may claim that an item is defective or broken, but the seller may not have the ability to challenge or dispute the claim effectively. Without a clear or consistent standard, it can be difficult for sellers to trust that their inventory will be treated fairly, especially when it comes to returned products that Amazon deems “unfit for resale” but may still have value.

- Limited Control Over the Returns Process:

- Lack of Seller Control: When using Amazon FBA, sellers have limited control over the entire returns process. Amazon handles the returns on behalf of the seller, meaning that sellers cannot interact directly with customers about returns, complaints, or issues. This limits the seller’s ability to offer a personalized experience to customers or resolve issues in a way that aligns with their brand values.

- Returns Sent to Amazon: All returns are sent back to Amazon fulfillment centers, not the seller directly, which means the seller cannot inspect or decide how to handle returns on their own terms. Returned inventory often ends up in a centralized Amazon warehouse, making it difficult for sellers to retrieve items or inspect the condition of the returns for potential resale. This also leads to a lack of control over repackaging or reconditioning returned products to resell at full price.

- Customer Service Restrictions:

- No Direct Customer Interaction: Amazon’s FBA service doesn’t allow sellers to directly interact with customers about returns. Sellers are restricted from managing customer inquiries about returns, damaged products, or dissatisfaction. Amazon’s customer service team handles all customer-facing aspects of the process, leaving sellers to rely on Amazon’s policies and decisions, which are not always in the seller’s best interest.

- Difficulty with Brand Loyalty: For many businesses, especially those with strong customer bases, being unable to engage directly with customers and offer personalized support during returns can result in lost opportunities to build loyalty. Sellers have no way of offering incentives for customers to keep the product, request replacements, or initiate exchanges instead of simply returning it.

3PL Returns Management: Greater Flexibility and Control

On the other hand, a 3PL provider offers a much more personalized and flexible approach to returns management, which can lead to better customer satisfaction and improved profitability. Here’s how a 3PL can improve your returns process:

- Customizable Return Policies:

- Seller-Controlled Return Policies: With a 3PL, businesses have the ability to create their own return policies that suit their business model. Whether you want to offer free returns, exchange programs, or store credits for returned products, a 3PL enables you to handle returns the way you see fit. This allows you to retain more customers by offering tailored solutions that align with your brand’s customer service philosophy.

- Flexible Time Frames: Unlike Amazon’s rigid return windows, 3PLs allow businesses to determine their own return time frames and return acceptance criteria. Whether you want to accept returns for a longer period or offer conditional returns (e.g., product in original packaging, unopened), a 3PL provides the flexibility to decide.

- Direct Control Over the Returns Process:

- Personalized Customer Service: With a 3PL, you can provide direct customer service regarding returns. If a customer is dissatisfied, you can communicate directly with them, offer personalized solutions, or address any issues related to the product. This direct engagement can lead to improved customer satisfaction and brand loyalty. Businesses can handle requests for exchanges, refunds, or even replacements with far more efficiency and personalization.

- Tailored Solutions for Returns: 3PLs give businesses more control over how returned items are handled. You can choose whether to restock returned products, refurbish or repair damaged goods, or even donate items based on the nature of the return. This control ensures that you can make the most of returned items, either by reselling them or recapturing some of the value through other means.

- No Restocking Fees or Arbitrary Charges:

- No Unnecessary Fees: Unlike Amazon FBA, where sellers may face restocking fees or penalties for returned items, 3PL providers typically do not impose these types of fees. Returned items are simply handled in accordance with the seller’s return policy. This removes any unpredictable costs associated with returns and helps sellers keep their costs under control.

- Restocking and Inspection: A 3PL allows businesses to inspect returned goods for quality, repack items if necessary, and decide if they should be restocked or sold through another channel. This ensures that you can maximize the value of returned products instead of letting them sit idle in a warehouse, as can happen with Amazon FBA returns.

- Streamlined Returns Processing and Tracking:

- Efficient Returns Logistics: Many 3PLs offer returns management software that helps track returns in real time, providing visibility into return reasons, item conditions, and stock status. With this data, businesses can better understand customer behavior, identify recurring issues with products, and improve overall product offerings.

- Reduced Processing Time: A 3PL can often process returns faster than Amazon, as you have more direct oversight of the process. Whether it’s handling returns through your own branded return portal or integrating with third-party returns software, 3PLs provide the tools needed to streamline the returns process.

- Enhancing Customer Loyalty Through Returns:

- Building Trust with Flexibility: By offering personalized return policies and providing a better customer service experience during the return process, businesses can build stronger relationships with customers. When customers feel like their concerns are addressed quickly and fairly, they are more likely to return to your business for future purchases. Loyalty is crucial in a competitive e-commerce landscape, and 3PLs enable sellers to foster this loyalty by giving them the freedom to offer flexible, customer-first return solutions.

The Hidden Costs of FBA Prep

One often-overlooked aspect of using FBA is the preparation requirements that come with sending inventory to Amazon’s warehouses. For many businesses, the FBA prep process can add significant overhead costs, logistical complexity, and operational inefficiencies. Understanding the hidden costs of FBA prep can help you determine whether partnering with a 3PL (third-party logistics provider) is a more cost-effective and streamlined option for your business.

FBA Prep: What It Involves and How It Adds Overhead

Before your products are sent to Amazon’s fulfillment centers, Amazon requires that they be properly prepped according to their strict guidelines. This process involves several specific steps to ensure that your inventory is properly labeled, packaged, and ready for storage at Amazon’s warehouses. Here’s a breakdown of the prep steps and why they can increase your operational overhead:

- Labeling Requirements:

- FBA Labeling Guidelines: Amazon requires each product to be labeled individually with unique Amazon barcodes (FNSKU), which must be affixed in a certain way to ensure that the product can be properly scanned and tracked within Amazon’s system.

- The Cost of Labeling: Many businesses find that preparing and labeling inventory themselves can be time-consuming and costly, especially when working with large volumes of products. Some businesses hire external labor or pay Amazon’s FBA prep services to handle the labeling, which adds additional labor costs. Alternatively, outsourcing this task to a 3PL often allows businesses to offload this responsibility to a professional service that can prepare the products more efficiently and at a lower cost.

- Packaging Specifications:

- Amazon’s Packaging Requirements: Amazon has strict guidelines for how products must be packaged, including the size, type of packaging, and the inclusion of any necessary padding or protective materials. Products must be packaged in a way that meets Amazon’s standards, which could involve wrapping, sealing, or bundling.

- The Overhead of Packaging: Many sellers find it costly and time-consuming to ensure their products meet Amazon’s packaging requirements. Additionally, if the packaging isn’t compliant, Amazon may refuse to accept the inventory or charge sellers for corrective actions. This is a hidden cost that can quickly eat into margins, especially for smaller businesses. Many sellers are forced to invest in specialized packaging equipment or outsource packaging to a prep center, further increasing costs and complexity.

- Polybagging and Bubble Wrapping:

- Special Requirements for Certain Products: Amazon requires products that are soft, delicate, or have small parts to be placed in poly bags or bubble wrap to ensure they are protected during storage and shipping. The prep process can involve ensuring that items are properly bagged, sealed, and labeled with the appropriate barcode.

- Additional Labor Costs: For small or delicate items, ensuring that each product is correctly polybagged or bubble-wrapped can involve significant labor. Businesses that rely on Amazon FBA may find themselves spending hours per week on this task. Some sellers opt to pay Amazon’s FBA prep services, but this incurs additional fees that eat into profit margins.

- Bundling and Kitting:

- Product Bundles: If you’re selling products in bundles or kits (e.g., a skincare set or a toy set), Amazon requires that each bundle be prepped and packaged as a single unit. This can involve manually assembling the items, labeling them, and ensuring they meet Amazon’s bundle criteria.

- Cost of Bundling: When bundling products, sellers must either perform these tasks in-house or pay for third-party services. Preparing bundles for Amazon’s fulfillment centers often involves both time and expense, and failure to meet Amazon’s bundling guidelines can result in fines or refusal to accept the products.

- Additional Fees for Prep Services:

- Using Amazon’s Prep Service: While Amazon offers prep services to help sellers with packaging, labeling, and bundling, these services come at an additional cost. For example, Amazon may charge $2.30 per unit for labeling, $1.00 per unit for polybagging, or higher fees for bundling. These costs can add up quickly, especially if your products require multiple forms of preparation.

- Hidden Overhead Costs: The ongoing prep fees from Amazon can significantly impact your margins. Unlike with a 3PL, where prep services are typically more affordable or included in the service, FBA prep costs can pile up without offering a corresponding increase in control or customization.

- Increased Lead Time and Delays:

- Inventory Preparation Time: The FBA prep process also increases the overall lead time for getting products from the manufacturer or supplier to Amazon’s fulfillment centers. This can delay your ability to fulfill orders quickly and efficiently, especially during peak seasons.

- Logistical Complexity: If your inventory needs to be prepped in different ways (e.g., polybagging one product, bundling another, and labeling a third), it adds logistical complexity to your supply chain, requiring additional time and resources to manage each step of the process. Businesses often need to hire more staff, invest in additional equipment, or outsource these tasks, increasing operational complexity.

How a 3PL Simplifies Prep and Reduces Overhead

In contrast to Amazon FBA’s rigid prep requirements, 3PL providers offer much more flexibility and cost-effective solutions when it comes to inventory preparation. Here’s how using a 3PL can help reduce the overhead and complexity of FBA prep:

- Customized Prep Services:

- 3PLs provide tailored prep services that are more cost-effective than Amazon’s FBA prep fees. Many 3PLs will handle everything from labeling and packaging to bundling and kitting, often at a lower cost than Amazon charges. Furthermore, these services are scalable, meaning you can adjust prep volume as needed, without the rigid costs associated with Amazon FBA.

- Reduced Labor and Equipment Costs:

- Instead of investing in specialized labeling equipment or hiring additional labor to handle prep, businesses can rely on 3PLs to manage prep efficiently and at scale. 3PLs have the expertise and systems in place to prep products quickly and with minimal overhead, allowing your business to focus on growth rather than day-to-day operations.

- Flexible Packaging Options:

- 3PLs allow for greater flexibility in packaging, meaning you can create a unique, branded unboxing experience for customers. Whether it’s custom boxes, inserts, or protective materials, 3PLs can provide the flexibility that Amazon’s rigid guidelines do not. This is especially important for businesses that want to maintain strong brand identity and customer loyalty.

- Comprehensive Inventory Management:

- 3PLs offer a more holistic approach to inventory management, where they handle everything from warehousing to fulfillment. This can include real-time inventory tracking, stock optimization, and demand forecasting, which can help reduce errors and the need for manual intervention in the prep process.

- No Hidden Prep Fees:

- Unlike Amazon FBA, where prep services come with additional charges, many 3PLs provide all-inclusive pricing for their services, including prep. This predictability in costs allows businesses to plan and budget more effectively without the surprise fees that can come with Amazon FBA’s prep services.

- Faster Time-to-Market:

- With 3PLs, businesses can speed up the time it takes to get products to market. Since the prep process is handled by professionals with established systems, there is less risk of delays due to mistakes in labeling, packaging, or bundling. This is especially important for businesses that need to fulfill orders quickly and maintain strong customer satisfaction.

Avoiding Amazon’s Increasing Restrictions

Amazon frequently changes its policies, and sellers are at the mercy of these updates. Sudden storage limits, changes in FBA fees, or even account suspensions can disrupt business operations overnight. Additionally, Amazon competes directly with many of its sellers by launching private-label products based on top-performing listings.

A 3PL reduces dependency on Amazon and offers businesses more stability. By diversifying fulfillment operations, businesses can mitigate risk and maintain control over their supply chain.

Amazon FBA’s Unpredictable and Restrictive Policies

- Frequent Policy Changes:

- Constant Updates: Amazon is notorious for frequently changing its policies around everything from fulfillment fees and storage limits to returns processing and account performance standards. Sellers are expected to keep up with these changes, often without warning or significant notice, and any failure to comply with the new rules can lead to costly penalties or even account suspension. For example, Amazon may adjust the fees charged for storage, impose new guidelines for labeling and packing, or change the criteria for performance metrics that determine seller eligibility for top-tier listings like Amazon Prime.

- Impact on Sellers: For small businesses or newer sellers, these constant changes can create confusion, disrupt supply chain operations, and increase administrative burden. Sellers may face unexpected increases in costs (such as higher storage fees during peak seasons) or be forced to scramble to adjust their inventory practices in line with Amazon’s evolving requirements. This lack of control can result in financial instability and frustration for business owners who need predictable conditions to scale.

- Sudden Storage Limits and Restrictions:

- Storage Limitations: One of the most challenging restrictions sellers face on Amazon is the ever-changing storage limits for their products. During peak times (e.g., Q4 holiday season), Amazon often places strict limits on storage in fulfillment centers. These limitations are based on factors like inventory turnover rates, sales performance, and even past performance metrics. Sellers may be caught off guard when Amazon imposes a sudden restriction on the amount of product they can store, forcing them to either pay inflated storage fees for excess inventory or experience delays in inventory replenishment.

- Overnight Impact on Operations: A business that relies solely on Amazon FBA may face inventory shortages or delayed restocking if Amazon suddenly enforces storage restrictions. This can cause delays in order fulfillment, resulting in poor customer satisfaction, negative reviews, and lost sales. Furthermore, sellers may have to pay for premium storage options (such as Amazon’s long-term storage fees) during periods when they’re not able to quickly move inventory.

- FBA Fee Changes:

- Increased Fulfillment Fees: Amazon frequently adjusts its fulfillment fees based on factors like product size, weight, and category. Sellers may find themselves subject to higher fulfillment fees for the same product due to an Amazon policy change. For instance, Amazon’s annual fee hikes in areas like storage fees, pick-and-pack fees, or shipping charges can chip away at sellers’ profit margins, especially when the price increases happen with little notice.

- Decreased Profitability: A sudden increase in fees can make products less profitable, particularly for low-margin businesses. Sellers who’ve already priced their products based on specific Amazon fees might find themselves in a position where the new fee structure results in negative profit margins, forcing them to either absorb the additional costs or increase prices—potentially making their offerings less competitive on the Amazon marketplace.

- Account Suspensions and Restrictions:

- Risk of Account Suspension: Amazon has stringent performance standards that sellers must adhere to. Sellers who do not meet Amazon’s performance metrics—including order defect rate (ODR), late shipment rate, or customer service standards—may face penalties, including account suspension. This means that businesses can be locked out of selling on Amazon and unable to fulfill orders, potentially for an extended period, without warning. Even a minor policy violation or customer complaint can result in penalties, and appealing a suspension can be a time-consuming and frustrating process.

- Loss of Access to Sales Channel: For businesses that rely exclusively on Amazon FBA, a sudden account suspension can mean losing access to one of their primary sales channels. In addition to the immediate loss of sales revenue, sellers may also face inventory holding fees, shipping delays, and brand damage, which can be difficult to recover from. With Amazon controlling the terms of service, businesses are at the mercy of Amazon’s decision-making, which can change without warning.

The Stability of 3PL Fulfillment: Reducing Dependency on Amazon

- Predictable and Transparent Pricing:

- Consistent Rates: One of the biggest advantages of working with a 3PL is that businesses can rely on predictable pricing. Unlike Amazon’s frequent and sometimes arbitrary fee increases, a 3PL often offers fixed rates for storage, handling, and shipping. This transparency allows businesses to better plan their expenses, avoid unexpected costs, and keep their profit margins intact.

- Flexibility in Service Plans: 3PLs also offer customizable fulfillment packages, meaning businesses can choose a service model that fits their needs. Whether they need on-demand storage, seasonal storage flexibility, or more cost-effective solutions for slower-moving products, 3PLs provide greater flexibility in choosing how inventory is handled, without the stress of unexpected fee hikes.

- No Unpredictable Storage Limits:

- Customizable Warehousing Solutions: 3PL providers offer more flexibility in storage compared to Amazon’s restricted warehouses. Instead of worrying about Amazon’s sudden storage limits during peak seasons, a 3PL can provide scalable warehouse space based on your current inventory needs. Additionally, businesses can negotiate seasonal adjustments for storage space, ensuring that they can handle increased inventory during peak sales periods without the risk of unexpected restrictions.

- Adaptability to Business Changes: 3PLs are also more adaptable when it comes to handling seasonal fluctuations in demand. During high-demand months, businesses can scale up their inventory and storage capacity, while during off-peak months, they can scale back without facing penalties or additional costs. This dynamic approach to warehousing offers a level of control that Amazon FBA does not.

- Mitigating the Risk of Account Suspensions:

- Reduced Reliance on Amazon’s Ecosystem: By using a 3PL, businesses can mitigate the risk of account suspensions or Amazon-imposed restrictions. Since the 3PL model allows you to sell across multiple platforms (Amazon, Shopify, Walmart, etc.), your business is not entirely dependent on one marketplace. Even if Amazon temporarily suspends your account, your products can still be sold through other channels, ensuring that your revenue stream remains uninterrupted.

- Customer Service Control: With a 3PL, you have greater control over customer service, including returns management, inquiries, and issues resolution. This ensures that your customers receive timely and satisfactory support without having to rely on Amazon’s customer service teams, who may be focused on standardized responses rather than personalized solutions.

- Multi-Channel Fulfillment (MCF):

- Sell Everywhere, Fulfill Anywhere: Many 3PL providers offer multi-channel fulfillment, which means businesses can sell on multiple platforms (Amazon, Shopify, Walmart, eBay, etc.) and have their orders fulfilled by the same 3PL. This approach reduces your dependency on Amazon’s ecosystem and gives you the freedom to diversify your sales channels. If Amazon suddenly implements a policy change that negatively impacts your business, a 3PL allows you to continue fulfilling orders through other channels, ensuring that your operations remain stable.

- Flexible Returns Management:

- Better Control Over Returns: With a 3PL, businesses have full control over how returns are handled, unlike Amazon, where returns can lead to penalties and lost inventory. Sellers can create flexible return policies, manage customer inquiries directly, and decide how to restock, refurbish, or donate returned items. This personalized approach to returns management helps businesses maintain better customer relationships and recover value from returned products.

When Should a Business Choose Fulfillment by Amazon (FBA)?

Amazon Prime & Reduced Shipping Costs for Customers

Working with FBA allows you to leverage Amazon Prime benefits. Customers will be more inclined to buy something with an Amazon Prime badge. As mentioned above, free shipping is a huge factor in online shopping decisions.

Integrations & Social Media Sales

Amazon offers the ability to use different e-commerce hubs such as WooCommerce, Shopify, and Wix. For companies selling on social channels, Amazon FBA connects to Facebook and Twitter to post listings there.

Flexible Costs & Scalability

When to Avoid FBA

There are a few reasons other fulfillment options may be better than FBA for your business.

- Companies with slim product margins: FBA costs cut into profit, and for companies that already have a small markup, this can seriously hurt profitability. Generally, sellers on Amazon suggest a minimum 250% markup on an average order to stay profitable.

- Companies with bulky or oversized products: Sellers with large items will need to find a 3PL that specializes in storing and shipping bulky goods.

- Companies where branding is important: If a company wants to customize packaging or add additional marketing inserts with their orders, choosing another 3PL or fulfilling orders themselves is a better route. For companies that desire a more personalized touch, FBA will limit their options.

- Companies with high shipping costs: The free shipping that Amazon provides to Prime members is absorbed by the seller. If a company has high shipping costs, this will hurt its overall profitability

When Should a Company Choose a 3PL Provider?

Availability of 3PLs Across the US

There are over 20,000 3PL businesses operating in the US alone. This gives a company many options when deciding which provider to work with, and effectively requires 3PLs to compete for business–which is great for sellers.

3PLs Provide Order Customization Options

Custom packaging can help a company grow its brand recognition. Working with a 3PL that supports specialty packaging can help a company provide a more personal experience and secure future repeat business.

3PLs Provide Lower Shipping and Storage Costs

Most 3PLs will have reduced shipping costs over listed rates. By leveraging their relationships, 3PLs pay less for shipping than businesses can often get on their own. Because shipping costs are often one of the highest costs a business pays, these cost savings add up to a business’ bottom line.

3PLs Give Better Customer Service

Though customer service ratings can vary by 3PL provider, many are able to provide exceptional customer experience by responding quickly to issues that occur, and providing clear and helpful communication with sellers. Phone calls are answered by trained staff, located onsite at the warehouse, who can promptly address any inquiries or issues.

What Are Some Common Issues with 3PLs?

Using a 3PL isn’t right for every business. Here are some issues that may arise that companies need to consider.

Companies with Low Order Volume

A small business or a new one with low order volume may not get much benefit in working with a 3PL. Until a business has a large enough shipping volume, it may prefer to keep fulfillment in-house.

Consider all Fees Associated with Using a 3PL

While 3PLs add significant value to the fulfillment process, fees can quickly begin to add up and rapidly cut into a business’ profit. For some businesses, these costs may be more than they can absorb. While businesses at scale typically achieve high returns through partnering with the right 3PL, it’s important to be aware of all of the costs involved with any prospective 3PL provider. 3PLs typically charge for services like:

- Storage—Depending on the 3PL, storage fees may be charged per square foot or per pallet.

- Receiving—When a 3PL receives truckloads, they often charge a flat fee per shipment received.

- Fulfillment—Additional value-added services like pick and pack, kitting, and order processing will add additional costs tacked on to an order.

- Shipping—A business will need to consider average shipping costs for orders. While many 3PLs can provide discounted rates on shipping, a business will need to compare these rates, along with other services, to select the optimal 3PL partner.

Choosing the Best Fulfillment Option for a Business

Regardless of your choice of fulfillment partners, outsourcing the fulfillment operations to specialist providers often helps a company focus on what it does best. For companies looking to integrate into and leverage Amazon’s network, FBA might be the best bet. If brand experience, customization, and customer service are more important, choosing a 3PL provider that aligns with a business’ goals is likely to be the better choice.

Choosing 3PL Services From Nautical Manufacturing and Fulfillment

If your business is considering partnering with a 3PL provider, talk to a Nautical representative to see if we’re a good fit. Nautical specializes in many fulfillment services your business needs to succeed. We also offer supply-chain services upstream, helping companies source high-quality, environmentally friendly products from markets around the world and transport them to your business at significant cost savings.