Building a strong relationship between buyers and sellers relies heavily on the quality of products. Proper quality control procedures are essential for a business of any size, and as a business grows it can be increasingly challenging to maintain a high standard for quality; this represents an existential threat that any company can ignore only at its own peril. Let’s take a look at quality control and its role in manufacturing.

Quality Control in Manufacturing

Quality control (QC) is the process of inspecting and measuring products to ensure they are consistent, free of defects, and up to the customer’s standards. It focuses on ensuring that a product meets a prescribed technical standard of quality (defined by requirements from the producer, the consumer, or both). To ensure the standard of quality, the QC process includes physically checking production activities during the entire cycle: from receiving materials, to the making of the finished goods, to packaging and shipping of the final product. Quality control focuses on identifying defects as they occur, so that no products leave the manufacturing facility faulty or incomplete.

A digital thermometer is a great example of a product that has multiple quality control checks. Someone who was testing the product would check that it:

- Provides accurate measures of temperature

- Correctly reads the desired temperature scale (Celsius or Fahrenheit)

- Has proper packaging that is protecting it during shipping and distribution

QC Process Example

How Does Quality Control Relate to Quality Assurance?

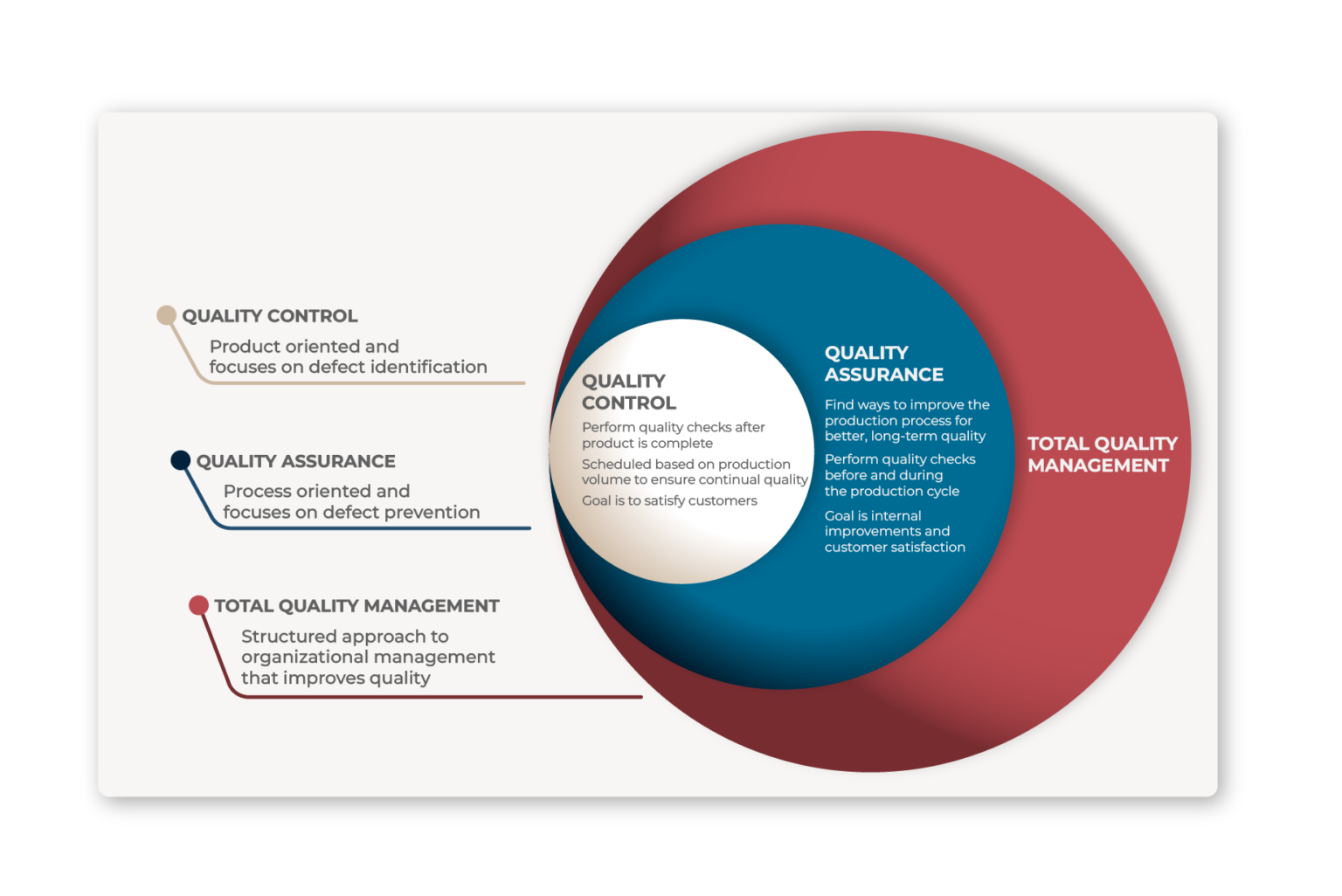

Quality assurance and quality control can sometimes be used interchangeably, but they are actually two different processes—or rather, overlapping parts of a larger set of overall quality management. While QC is product-oriented and is focused on identifying quality issues in manufactured products, QA is process-oriented, and it focuses on planned events and procedures to prevent quality issues and defects from occurring in the first place. Quality Control is typically looked at as a subset of activities relating to a set of Quality Assurance procedures. By proactively preventing manufacturing defects, QA helps make operations more efficient and reliable. It requires organizational planning and continuous testing and monitoring.

Taken together, QC and QA processes are part of a Total Quality Management (TQM) system.

Why is Quality Control Important?

Minimizing defects in production reduces waste, which drives down production expenses. It also saves a company the impact to its brand when faulty products end up in consumers’ hands, resulting in returns or worse—recalls. At the end of the day, providing quality products to customers helps build trust and brand loyalty, which is critical to the lifetime value that consumers can ultimately bring to a business.

Quality Control Methods and Techniques

The following techniques are used by producers to ensure products arrive to consumers defect-free.

Inspections

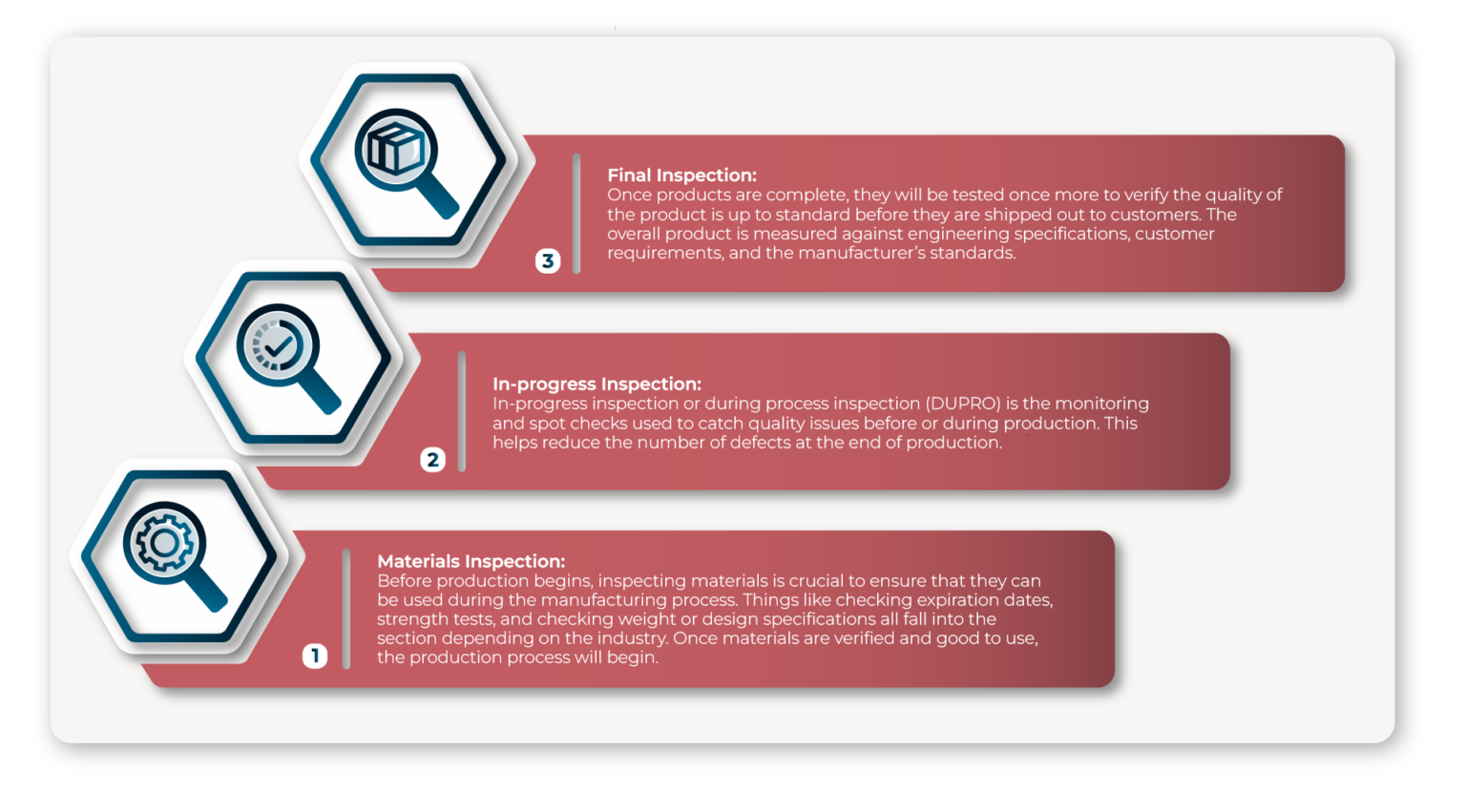

When most people think of quality control, this is probably what they picture. Inspections are used in many industries and can be broken into three main points during the manufacturing process.

Materials Inspection: Before production begins, inspecting materials is crucial to ensure that they can be used during the manufacturing process. Things like checking expiration dates, strength tests, and checking weight or design specifications all fall into the section depending on the industry. Once materials are verified and good to use, the production process will begin.

In-Progress Inspection: In-progress inspection or during process inspection (DUPRO) is the monitoring and spot checks used to catch quality issues before or during production. This helps reduce the number of defects at the end of production.

Final Inspection: Once products are complete, they will be tested once more to verify the quality of the product is up to standard before they are shipped out to customers. The overall product is measured against engineering specifications, customer requirements, and the manufacturer’s standards.

Statistical Quality Control

Statistical quality control (SQC) is a set of statistical techniques and methods used to monitor and control the quality of products. It involves the application of statistical methods to analyze data and make decisions about the quality of a product or process based on that data. In practice, it typically means that a manufacturer collects and records data against specific requirements for a product to ensure they meet specifications for size, weight, color etc. SQC ensures that a product or process consistently meets or exceeds the required quality standards in a data-driven way.

Total Quality Management

Total Quality Management (TQM) is a comprehensive management approach that aims to involve all members of an organization in the continuous improvement of quality. It requires a cultural shift within an organization, with a focus on teamwork and continuous learning to ensure product excellence.

Acceptable Quality Limit Sampling

Acceptable quality limit (AQL) sampling is a method to ensure that an order has met the specific specifications that the manufacturer and customer agree on prior to the manufacturing process. The AQL is the worst quality level that is tolerable for a product. This level will vary for different products. An example of this is with medical equipment. Because of the potential harm from a defective product, the AQL must be much lower.

Why Quality Matters Over Quantity in Production

Quality and quantity are two of the most important production factors to consider. Increasing internal expectations or customer demand can put pressure on manufacturers to sacrifice quality control procedures to meet market opportunities. Having sufficient product to meet demand is necessary to capitalize on revenue potential. However, every business needs to consider the long-term effect of prioritizing quantity over quality.

Increased Competition: For many different product categories, there is a large pool of competitors fighting for market share of low-quality products due to lower costs. This has become even more relevant with a large increase in dropshippers in the past few years. This crowded landscape can be difficult to traverse and make your product stand out among the many other similar quality products on the market.

Bad Reputation: Ramping up production in a way that results in lower-quality products will erode a business’ reputation, by way of poor customer experiences, which create a vicious cycle ultimately leading to fewer sales. This is compounded by higher costs resulting from returns processing, customer service calls, and other expenses related to poor consumer experience. A shift in a company’s reputation may be gradual and go unnoticed for a period of time, but it can be an insidious profit-killer that can be challenging to recover from.

Fewer Growth Opportunities: Scaling to penetrate a new market for quick revenue gains can be a lucrative proposition, but should be carefully considered if it results in a degradation to quality control. When products are of a lesser quality, it may be difficult to win in new markets—especially if quality substitutes already exist. Businesses in these markets may be reluctant to partner with a company with a poor reputation

Choose a Manufacturer with a Quality Program

Even if a business desires to produce a lower-grade product, working with a manufacturer that emphasizes quality management is essential. While conducting due diligence on prospective business partners, consider their:

Quality Control Measures: Make sure they have quality control measures in place. This can include on-site quality control specialists, staff training programs, or any other systems that can allow the manufacturer to produce quality products.

Experience: Experience is often a signifier of a manufacturer’s capacity to produce at standards of quality. Any producer that’s been around for a while has likely improved operational efficiency through quality control. . Inquire with other companies who are supplied by a manufacturer to ensure they consistently deliver at expectation.

Materials: Check to make sure that the manufacturer is using quality raw materials or components to fabricate the products they supply to partners. Substandard inputs can lead to quality issues downstream, so quality at the source is imperative.

Creating Quality Products With Nautical

Nautical was built on a foundation of providing high-quality services and products to our partners worldwide. We conduct rigorous quality control inspections to stay in compliance with our customer’s high standards—and our own. Nautical knows quality, and we guarantee satisfaction to all of our partners, large and small.

Quality Control FAQ

What Is Quality Control in Manufacturing?

Quality control (QC) is the systematic procedure of examining and gauging products to verify their uniformity, absence of flaws, and alignment with customer-defined standards. Its primary objective is to guarantee that a product adheres to specified quality benchmarks, which may be set by the manufacturer, the consumer, or both parties involved.

What’s the Difference Between Quality Control (QC) and Quality Assurance (QA)?

Quality control is a reactive process that involves inspecting, testing, and correcting defects in products or services after they are produced, aiming to meet predefined quality standards. Quality assurance, on the other hand, is a proactive process that focuses on preventing defects from occurring by establishing and adhering to quality standards and procedures throughout the entire production or service delivery process.

What’s the Quality Control Process?

The quality control (QC) process encompasses defining specific quality standards, planning QC activities, sampling representative products or services, and conducting inspections and tests to ensure they meet the established standards.