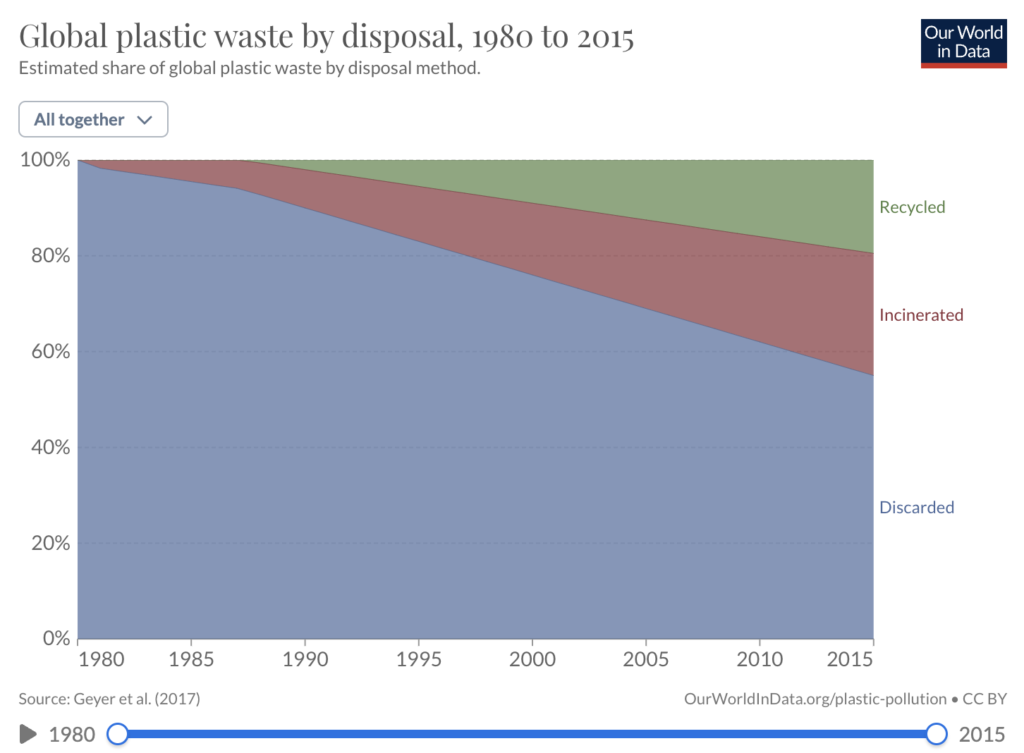

Concern over the environmental impact of plastic pollution has been growing for decades—and more and more third-party groups are starting to raise the alarm. But a response to our global plastic challenge (one that mitigates the current problem without creating any new ones) has yet to materialize in a way that everyone can agree upon. While lawmakers in Europe and the US are eyeing legislation that would require companies to back up their sustainability claims, other governments like Canada are pledging to ban single-use plastics entirely. We’re watching the world negotiate plastic policy in real-time. It’s in our collective global interest to compel decision-makers to leverage the best available science and collaborate with all stakeholders to reframe the way we produce, design, use, reuse, and dispose of plastics–and build an effective circular economy for plastics that benefit all players in the world market equitably.

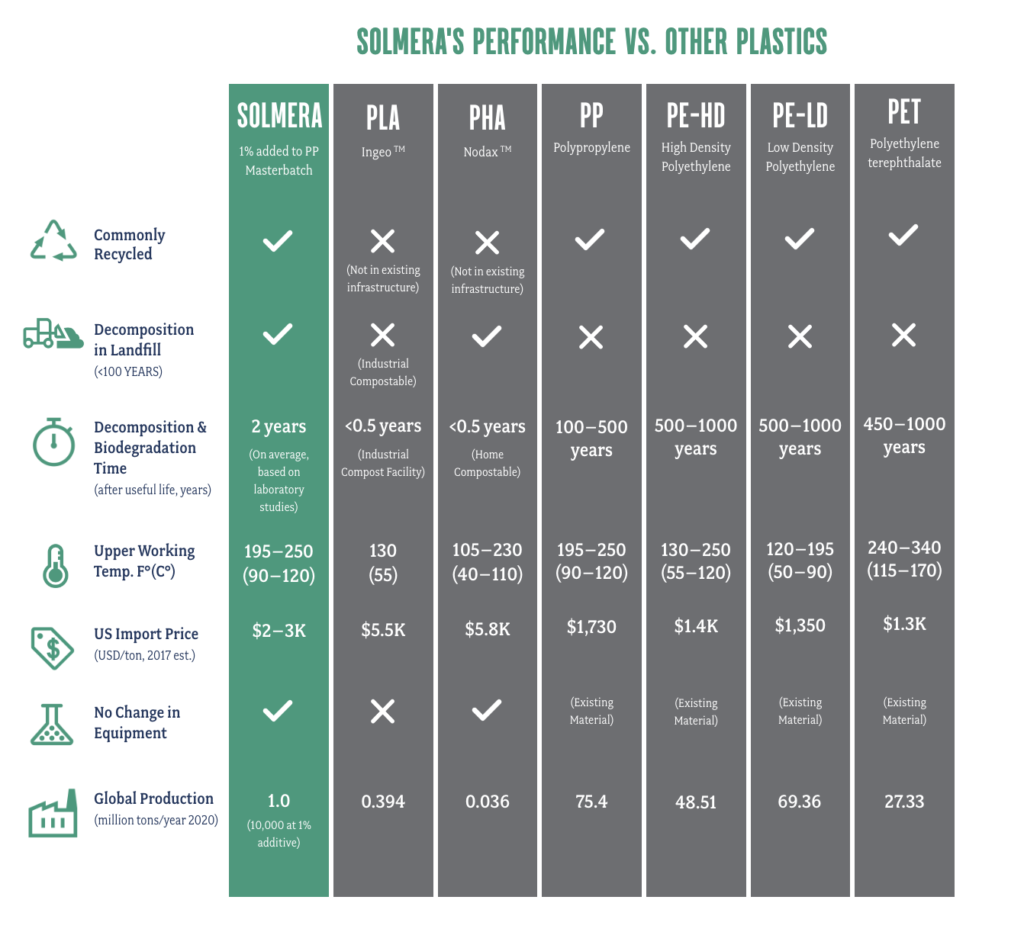

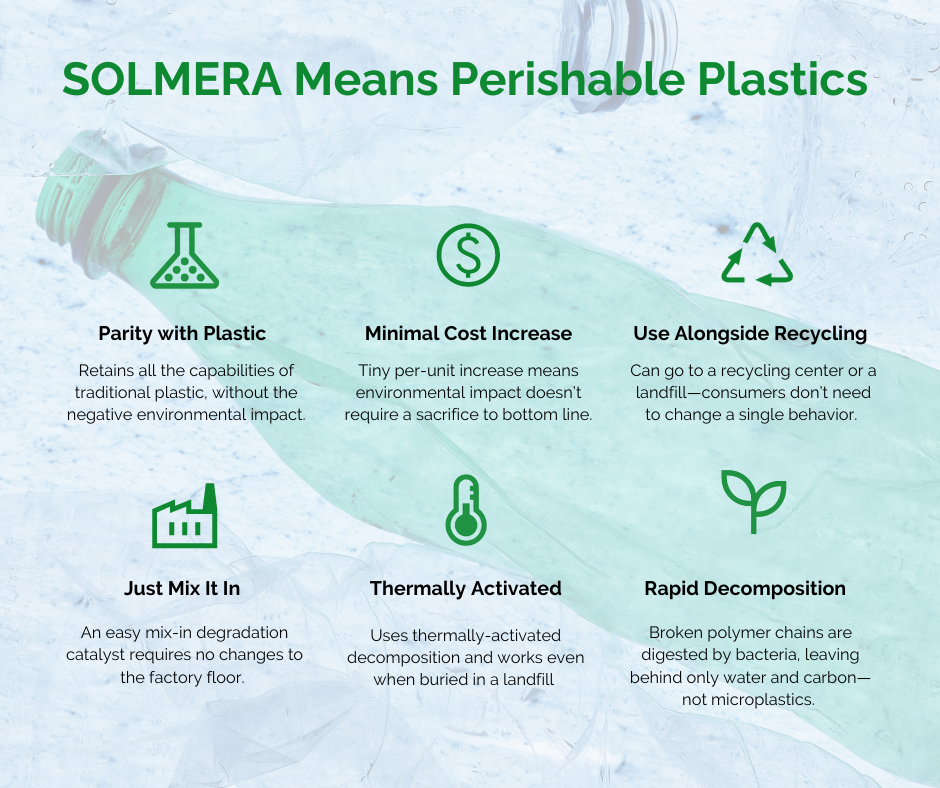

There are many reasons why the plastic pollution problem is a formidable challenge. Many plastics can’t be recycled. Or if they can be, they often aren’t. Producing biodegradable plastics that otherwise retain the same characteristics as their non-green counterparts has been an intractable manufacturing quandary. Even when technologically possible, green plastics have been prohibitively expensive. That is, until Solmera™—a groundbreaking new plastic additive that can be added to most single-use plastics to rapidly break them down. Solmera products are made of perishable plastics that can be used in virtually any environment and leaves only biomatter behind (no microplastics).

Solmera is distributed by Polaris Trading Solutions and is beginning to make big waves in the plastics industry through its innovatively low-effort approach to combating the plastic problem. Thanks to Solmera, we don’t have to change consumer behavior; in fact, we barely have to change anything at all—the only adjustment is a pennies-on-the-dollar tweak to plastic production. Nautical is proud to offer Solmera products to our customers.

“Plastic pollution is an environmental, wildlife, climate, human health, and social justice issue. People and communities across the world are finally waking up to the fact that plastic pollution impacts everything.”

Plastic Pollution Coalition

How Solmera Makes Plastics Perishable

Solmera is the world’s most affordable sustainable plastic. As an additive, it’s mixed in with traditional plastic pellets during manufacturing. Effectively a “drop-in solution,” the compound integrates directly into existing technology. It is FDA and EU compliant and certified non-toxic.

Solmera has applications in all types of plastics categories. Some of these include:

- Food Service

- Personal Care

- Home Care

- Absorbents

- Rigid Plastics

- Agriculture

Because Solmera was introduced to tackle plastic waste, it takes aim at the biggest pollution offenders first—PP and PE products. Companies wishing to reduce the environmental impact of their packaging struggle to find alternatives for these hard-to-recycle items. Although Solmera cannot reduce the production of plastics, it can significantly shorten the end of life in the wastelands.

A main benefit of using Solmera is that it doesn’t compromise the physical properties of the plastics batch it is added to until the end of its shelf life, Giving companies a cost-effective, eco-friendly solution without sacrificing quality. Let’s take a look at the process from production to decomposition.

Plastic Production for a Better Tomorrow

SOLMERA plastics are made from conventional polymers with a low (typically 1% / BOPP film 2%) addition of a prodegradant masterbatch. The active ingredients are embedded in a carrier resin that matches your existing masterbatch (e.g. ExxonMobil Paxon™ AD60-007 resin for HDPE). No change to production equipment is needed. The additive is lab tested to be 100% perishable in 4-6 years for times when products aren’t properly disposed of. If littered, it will still safely biodegrade and be removed from the environment much quicker than ordinary plastic products that are littered today.

Recycle or Discard to a Landfill with an Easy Conscience

The Solmera compound does not impact the recyclability of plastics. When mixed with conventional plastics in the recycling process, the active compound becomes too diluted to break down resynthesized plastics. Due to higher ambient landfill temperatures which are more than sufficient to trigger Solmera plastics to decompose.

Thermally-Activated Decomposition Does it Better

Significant degradation begins once exposed to above-room temperature conditions at the end of the product’s shelf life. There is no need for special UV light or other treatments to aid perishable plastics to degrade and biodegrade. Once activated the rate and extent of oxidation of the polymer is accelerated which leads to molecular weight reduction. Polymers will become bio-available and polymer chains are digested by bacteria, yielding only carbon dioxide, harmless salt, and water. This process, which previously would have taken hundreds of years, is cut down to just a few short years.

Why is Solmera Better Than Other Alternative Plastics?

Solmera isn’t the first sustainable plastic alternative. However, many things make it stand out from the field. For one, it doesn’t require any additional attention. Solmera products don’t need extra machinery and don’t require special sorting once the product has been disposed of. Solmera is one of a few alternatives that will decompose in regular landfill conditions and is the cost leader among other such solutions.

Other Key Benefits Include

- Functional with rigid and flexible plastics with high transparency

- Compatible with most recycled and recyclable resins

- No microplastics