Good businesses are always looking for new ways to capture customers’ attention. One area that companies may overlook—at their peril—is product packaging. A bevy of research finds that product packaging influences buyer behavior. Plastic often plays an important role in product packaging, but many businesses are looking to reduce their plastic footprint. Packaging methods that generate less plastic waste are gaining favor—and glue tipping is one approach that more producers are leveraging to meet the increasing green sensitivity of their consumers.

Product samples, which also often rely on appealing packaging, can help businesses increase brand trials and interactions, leveraging methods such as flow wrap sample packaging, assembly kits, and other product demos to help decrease consumer purchase risk. Tipping is a popular option for product samples due to its versatility and sleek application.

What is Glue Tipping?

Glue tipping, also known as tip-on gluing or simply tipping, is a method of attaching a product, product sample, or gift card to a printed envelope or literature card (When you receive a new credit card in the mail, your card is attached to a sheet of paper using glue-tipped adhesive). Glue tipping provides producers with more versatility in packaging and presentation, and can be achieved in as little as a few steps:

Step One– Alignment: The promotional item to be glued is placed on the printed material in a way such that all promotional text is visible, and other aesthetic and physical features (like balance) are pleasing. It’s also important to ensure your machine is calibrated and set up for the specific production run.

Step Two– Attachment: A thin layer of adhesive glue (also referred to as fugitive or booger glue) is applied to the back of the promotional item, then placed on the print material precisely. This process is typically handled by a tipping machine to allow for rapid, efficient production.

Step Three– Review & Use: The glued items are checked for quality to make sure they are up to the company’s quality standards and will result in favorable consumer experiences.

Glue tipping can be combined with other packaging methods to create satisfying customer experiences:

- Folding + tipping: fold card stock or paperboard into a rectangular, envelope-like shape, then tip on an item onto the center panel to create a pleasing presentation.

- Die cutting + tipping: die cut your printed material into any geometric shape, then tip on your product for some extra pizazz!

- Tipping + shrink wrapping: add shrink wrap over each tipped piece for a professional finish that also provides extra protection.

Benefits of Glue Tipping

There are many reasons why glue tipping is a highly-appealing alternative to traditional plastic packaging for many producers.

Cost Effectiveness: By directly attaching their product directly to print material, a business can effectively eschew traditional packaging and avoid the additional charges associated with plastic wrap, which is commonly used in regular plastic packaged items. The reduced need for extra material and assembly costs results in significant savings.

Sustainability: Using glue tipping greatly reduces plastic waste by eliminating the need to use plastic for primary and secondary packaging.

Limitations with Using Glue Adhesive

Like any other packaging methods, glue tipping may not be the most appropriate option for certain product dimensions or uses.

Product Shape: Glue tipping is mainly used with flat or mostly-flat objects. When packaging bulky products or ones that are too curved or angular, tipping may not be able to provide the necessary adhesion to secure them.

Less Protection: Tipping alone doesn’t use any outer barrier to protect the product, which can risk damaging the item or printed material. Glue tipping can be combined with additional product packaging to enhance the presentation or protection of the item, but this may limit the cost benefits of using it versus traditional packaging methods.

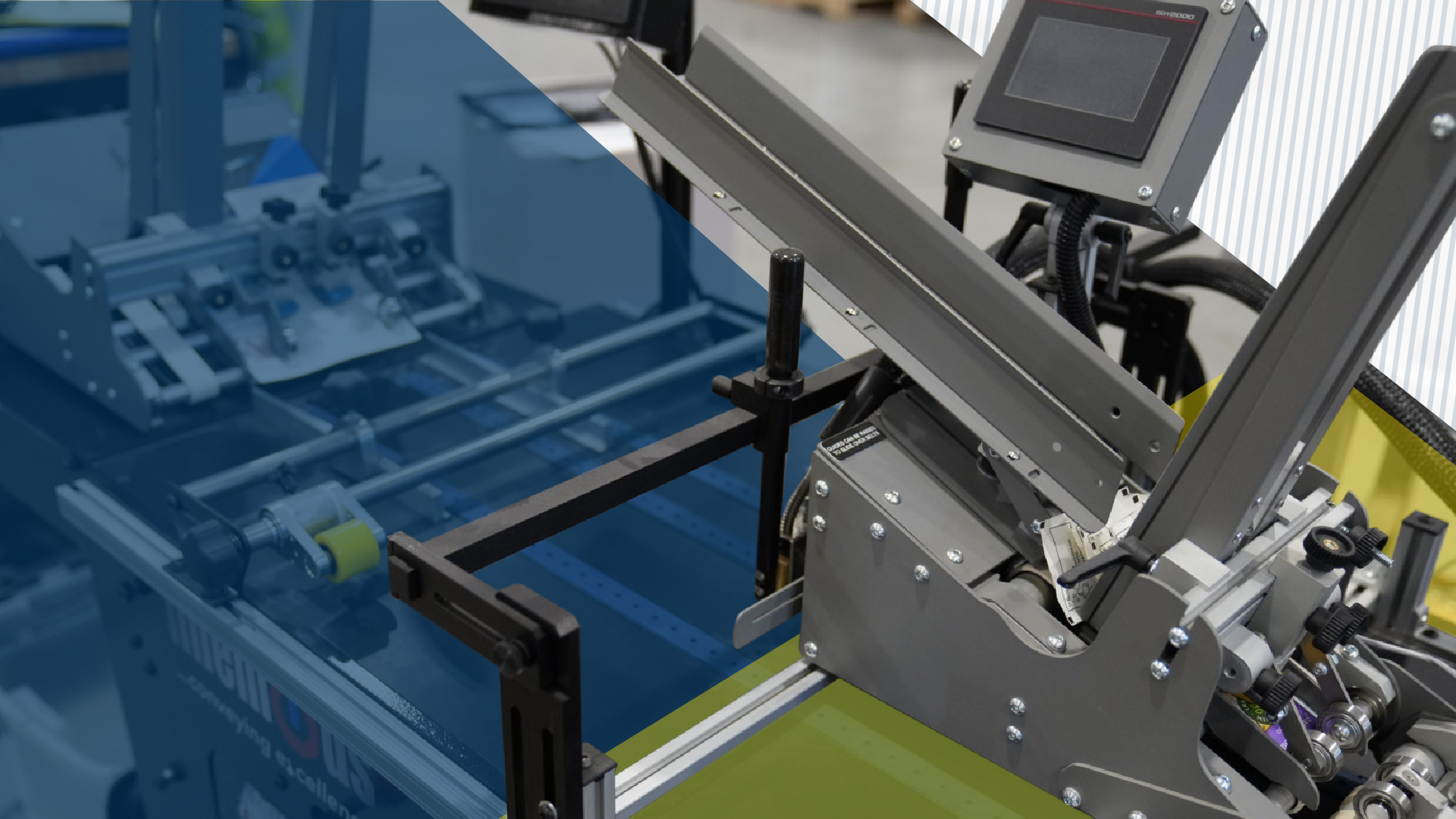

Tip on Glue with Nautical

For all of your packaging and product sampling needs, Nautical has a state-of-the-art facility in Kansas City equipped with a high-speed tipping machine. Our tipping machine is custom-made, allowing us to tip items that aren’t flat (tea bags, candy bars, etc.)—and can produce up to 300 units a minute. We also partner with Solmera™ to provide perishable plastic alternatives for packaging that necessitates plastic components. Depending on your packaging needs, we’ll work closely with you to ensure you create the best possible customer experience.