Today’s globalized economy requires businesses to constantly seek out ways to produce high-quality products efficiently while keeping costs low. That’s where contract manufacturing comes in—a solution that allows companies to outsource their production to specialized manufacturers. From electronics to pharmaceuticals, industries across the board rely on contract manufacturing to meet market demands without the need for extensive in-house facilities or labor.

In other words, contract manufacturing is a sourcing strategy a company may choose to leverage to outsource some part of the manufacturing process to a third-party business partner. Contract manufacturers can produce components or the finished products for the business. The company may also choose to outsource the packaging of the goods to the same firm (or a specialized packager)—through a separate strategy called contract packaging. By taking advantage of available production capabilities and expertise, a company can quickly take a product to market and potentially achieve a competitive advantage over similar services.

Let’s take a deeper look at what contract manufacturing is and how it can be successfully utilized to build more business.

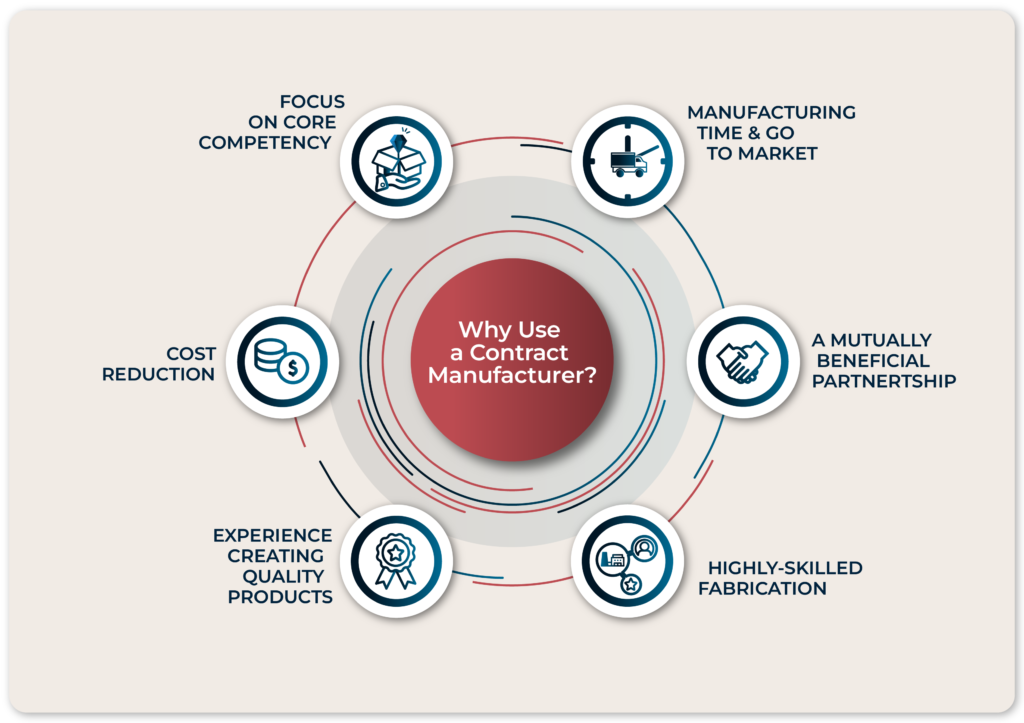

Why use a contract manufacturer?

Companies may lack the resources, time, or capability to produce parts or finished goods on their own. Large up-front equipment and machinery costs can create high barriers of entry for new product lines, and contract manufacturing is often an appealing alternative to significant capital investment. Here are the main benefits of outsourcing parts of manufacturing to a third-party partner.

Cost Reduction

Cost reduction can be a primary motivating factor in a company’s decision to outsource manufacturing. Avoiding large investments in equipment and maintenance costs can save companies big. This may also include labor costs, as contract manufacturers provide their own employees for the project. Additionally, the manufacturer can often achieve a lower cost-per-unit produced thanks to the economy of scale their plant has reached.

Focus On core competencies

With inefficiencies of production outsourced externally, a company is freed to focus on profit-driving operations. This better focus can also extend to new research and development opportunities, allowing the business to innovate more quickly and stay ahead of the competition. Working with a contract manufacturer allows a company to spend more time focused on adding value in ways aligned to its unique value proposition.

Manufacturing Time and go to market

By working closely with a third-party manufacturer, companies can cut down on the time it would take them to independently bring a product to consumers. The manufacturing partner can commit to production timelines that align to a go-to-market strategy, whereas an in-house job is more likely to be subject to delays and other complications. By reducing manufacturing time, a company gains an edge taking a good to market.

a mutually-beneficial partnership

A strong partnership can bring value to both a business and its contract manufacturing provider for many years to come. The reliable stream of revenue for the partner will ensure they continue to live up to quality expectations, further reinforcing the arrangement.

Highly-skilled fabricators

Partnering with a third party allows a company to take advantage of skills and technology that they may not possess in-house. The partner manufacturer is also likely to benefit from existing relationships with other industry experts that they can draw from to improve production quality or reduce cost. Access to this knowledge can help a company achieve a competitive edge.

Experience creating quality products

Contract manufacturers are likely to have developed procedures for quality control that help them detect defective or damaged materials early. Catching quality issues before they reach a customer can save a business customer services expenses and damage to its reputation.

Types of Contract Manufacturing Services

Contract manufacturing services come in various forms, allowing companies to choose the level of outsourcing that best fits their needs. From full-scale production to specific manufacturing tasks or private label solutions, contract manufacturing offers flexibility for businesses of all sizes and industries. Here’s a look at the primary types of contract manufacturing services: End-to-End Production, Partial Production Services, and Private Label Manufacturing.

1. End-to-End Production

End-to-End Production is a comprehensive service where the contract manufacturer manages the entire production process from start to finish. This type of service is ideal for companies that want to completely outsource production while focusing on areas like research, development, branding, and distribution. With end-to-end production, the manufacturer takes responsibility for:

- Raw Material Sourcing: Securing all necessary raw materials and components, often leveraging established supplier relationships for quality and cost savings.

- Manufacturing & Assembly: Handling every stage of production, from initial assembly to final product completion.

- Quality Control: Conducting rigorous testing and quality checks to ensure the product meets the client’s specifications and industry standards.

- Packaging & Labeling: Completing the final presentation of the product, including branding elements like labels and packaging, so it’s ready for retail.

End-to-end production provides a one-stop solution for companies looking for full support in manufacturing without the need to manage multiple suppliers or production steps.

2. Partial Production Services

For companies that want to retain some control over their production but need specialized support in certain areas, Partial Production Services are an effective option. In this model, the contract manufacturer handles specific parts of the manufacturing process, such as:

- Component Assembly: Where a company supplies key materials or components, and the contract manufacturer performs the assembly.

- Sub-Assembly Manufacturing: Producing only a portion of the final product, often for complex items with multiple components or parts.

- Packaging and Labeling: Companies may choose to outsource only packaging and labeling, allowing the contract manufacturer to prepare products for sale according to the brand’s specifications.

Partial production services provide flexibility for companies that may have in-house capabilities but need help with specific processes or want to ramp up production quickly without overhauling internal operations.

3. Private Label Manufacturing

Private Label Manufacturing is a specialized service where the contract manufacturer produces generic or pre-designed products that the client can brand and sell under their own name. This is especially popular in industries such as cosmetics, nutritional supplements, and food and beverages, where standard formulations are widely available. Private label manufacturing involves:

- Product Customization: Allowing some level of customization in terms of formulation, packaging, and branding while relying on the contract manufacturer’s base product.

- Brand Labeling: The final product is labeled with the client’s brand, logo, and design, making it look like a proprietary product even though the actual production is handled externally.

- Quick Market Entry: Private label manufacturing allows companies to rapidly introduce products without going through the lengthy and costly process of product development.

Private label manufacturing is an attractive option for brands that want to expand their offerings without investing in R&D or production infrastructure, as it enables them to leverage a manufacturer’s existing product portfolio and expertise.

Which industries use contract manufacturing?

Contract manufacturing spans many industries with each needing something a bit different from their manufacturer. These industries include.

Electronics: It’s no surprise that many of the tech hardware giants leverage a contract manufacturer for their components and products (smartphones, laptops, smart appliances). By working with a contract manufacturer, they can focus on their product development and software innovation.

Plastics: Companies that either sell or use plastics often use outsourced manufacturers who are experts in different plastic processing methods such as thermoforming, injection molding, and many other methods.

Automotive and Aerospace: Like the other industries, automotive companies use contract manufacturers for most of the components in the vehicle (and even sometimes for vehicle assembly). This is very similar to the process for aerospace companies as well. Contract manufacturers handle and create parts for helicopters, airplanes, and any other aircraft.

Medical: In the medical industry, contract manufacturers are often specialized. They must adhere to standards of high quality and must meet the regulatory requirements to be used in health and medicine.

Food and Beverage: Companies in the food and beverage industry rely on contract manufacturers for most of the ingredients that enable them to meet demand. Ingredients, packaging materials, and containers are just some of the things these manufacturers help with. In addition to these services, many companies also use contract packaging and repackaging services for many of their products.

How Contract Manufacturing Works

Contract manufacturing is a collaborative process involving multiple stages, from initial planning and agreement to final delivery of the product. Here’s a closer look at how contract manufacturing works, covering the initial steps, supply chain coordination, quality assurance, and logistics & delivery.

1. Initial Steps

The contract manufacturing process begins with an agreement between the hiring company and the manufacturer. During this stage, both parties negotiate terms that outline each side’s responsibilities, production specifications, quality standards, pricing, timelines, and confidentiality or intellectual property protections. This contract forms the foundation of the partnership, ensuring clear expectations and accountability.

Once the contract is in place, the manufacturer creates a detailed production plan that includes timelines, materials sourcing, staffing requirements, and equipment needed to meet the client’s production demands. For companies with specific product designs or regulatory requirements, the manufacturer may also conduct a trial run to confirm that all elements align with the client’s standards before full-scale production begins.

2. Supply Chain Coordination

An essential part of contract manufacturing is managing the supply chain. In some cases, the client supplies certain raw materials or proprietary components; in others, the contract manufacturer takes full responsibility for sourcing materials. This coordination requires aligning with suppliers for consistent, quality input materials to meet production timelines and specifications.

During this phase, both parties work together to set up systems that keep the supply chain running smoothly, such as tracking materials in real time and coordinating with suppliers to ensure they meet quality and delivery expectations. Strong supply chain coordination is crucial to avoiding delays and disruptions, as any gap in materials can halt production and affect final delivery timelines.

3. Quality Assurance

Quality control is critical in contract manufacturing, especially for industries where safety and compliance standards are stringent, like pharmaceuticals or automotive. The contract manufacturer must adhere to the quality benchmarks set forth in the initial agreement. These benchmarks often include compliance with industry-specific certifications, like GMP (Good Manufacturing Practice) for pharmaceuticals or ISO standards for various sectors.

Throughout the manufacturing process, quality assurance teams conduct inspections and tests at multiple stages, from incoming materials to final products. Many companies and manufacturers also implement regular audits to ensure that the production process meets both industry and client-specific standards. Consistent quality control helps prevent costly recalls or product issues and ensures that the end product aligns with the company’s brand standards.

4. Logistics & Delivery

Once production is complete, the final step involves organizing the logistics for transporting and delivering the finished products. In many contract manufacturing agreements, the manufacturer is responsible for packaging and shipping directly to the client’s warehouses or, in some cases, directly to retailers or end customers.

The logistics process includes coordinating shipping timelines, managing customs or regulatory paperwork (for international shipments), and ensuring safe handling to protect product quality during transit. Many contract manufacturers work closely with logistics providers to manage costs and ensure timely delivery, helping the client achieve a seamless distribution process without additional overhead.

Contract Manufacturing vs. Other Outsourcing Models

When businesses consider outsourcing production, they often encounter various models, including contract manufacturing, OEM (Original Equipment Manufacturer), and ODM (Original Design Manufacturer). Understanding the differences among these models is crucial for companies looking to optimize their production strategies and meet market demands efficiently. Here’s a closer look at how contract manufacturing compares to both OEM and ODM.

1. Comparison to OEM (Original Equipment Manufacturer)

OEM refers to a manufacturing model where a company produces parts or complete products that are then sold under another company’s brand name. In this arrangement, the OEM typically manufactures products based on specifications provided by the client. Key characteristics of the OEM model include:

- Product Design: The client company usually provides the design and specifications for the product, while the OEM focuses on the manufacturing process.

- Branding: The end products are marketed under the client’s brand, but the OEM often remains unnamed in the consumer market.

- Customization: OEMs may have limited flexibility to modify designs beyond what is specified by the client, as their primary role is to produce according to given parameters.

In contrast, contract manufacturing encompasses a broader scope. While it may include aspects of OEM services, contract manufacturers often take on more comprehensive roles, including sourcing materials, assembly, and quality control. Contract manufacturers may also offer their expertise in product development, allowing clients to leverage specialized skills or technology.

2. Comparison to ODM (Original Design Manufacturer)

ODM differs from both contract manufacturing and OEM by providing both design and manufacturing services. ODMs create products based on their own designs and specifications, which are then sold under a client’s brand. The main features of the ODM model include:

- Design Ownership: ODMs take full responsibility for product design and development, allowing clients to focus on branding and marketing without needing to invest in product development.

- Custom Solutions: Clients can often request modifications to existing designs, but the ODM retains the design rights and usually offers a catalog of products for clients to choose from.

- Time Efficiency: By leveraging existing designs, companies can bring products to market quickly, making ODMs a popular choice for brands looking to expand their product lines rapidly.

In summary, while OEM focuses primarily on manufacturing according to the client’s specifications and ODM combines design with manufacturing, contract manufacturing offers a more flexible approach. It can range from comprehensive production management (including sourcing and quality control) to specific manufacturing tasks, depending on the client’s needs.

Risks of contract manufacturing

With all of the stated good reasons to work with an external manufacturing supplier, it’s important to consider some of the issues that can occur.

Lack of production control

For both parties, it can be difficult to modify production once it begins. Strong communication is critical to a successful partnership. For the originating company, after they communicate the specs of a product and any other order information, little can sometimes be done to directly monitor the manufacturing process. On the manufacturer’s side, they have little recourse to make improvements or modifications to production to streamline fabrication issues without risking contract obligations.

Risk of low-quality products

If outsourcing an existing product, it’s important to conduct thorough research before choosing a contract manufacturer to avoid a dropoff in product quality. A business should select a manufacturing partner with a comprehensive QA process to help them check, measure, and test products and compare them to the business’ specific compliance requirements. For new products, be sure to adequately compare production samples to prototypes to ensure fidelity of design and execution.

Employee layoffs

Any company moving production to a third party will have to consider how layoffs will affect employee morale and company culture. For many businesses, this consideration can greatly upend any cost-saving benefit they might receive from working with a contract manufacturing provider.

Trends Shaping the Future of Contract Manufacturing

As the global market continues to evolve, several key trends are influencing the future of contract manufacturing. Businesses are increasingly looking for ways to enhance efficiency, sustainability, and responsiveness to market demands. Here are three significant trends shaping the landscape of contract manufacturing: Automation and Smart Manufacturing, Sustainability Practices, and Regionalization of Supply Chains.

1. Automation and Smart Manufacturing

The rise of automation and smart manufacturing is transforming how products are manufactured. Advancements in robotics, artificial intelligence (AI), and the Internet of Things (IoT) are streamlining production processes, reducing costs, and enhancing precision.

- Increased Efficiency: Automated systems can perform repetitive tasks with high accuracy and speed, significantly increasing production efficiency and output. This allows contract manufacturers to meet high-volume demands without sacrificing quality.

- Real-Time Monitoring: IoT technology enables real-time monitoring of manufacturing processes, allowing for quick adjustments and improvements. Manufacturers can gather data to optimize operations, predict maintenance needs, and minimize downtime.

- Customization and Flexibility: Smart manufacturing technologies enable a higher degree of customization, allowing companies to adapt quickly to changing consumer preferences without the need for significant retooling or process changes.

These advancements not only improve productivity but also provide a competitive edge in a rapidly evolving marketplace, making automation a crucial component of modern contract manufacturing.

2. Sustainability Practices

As consumers and regulators increasingly prioritize environmental responsibility, contract manufacturers are adopting sustainability practices to reduce their ecological footprint. This trend encompasses various initiatives:

- Eco-Friendly Materials: Many manufacturers are exploring the use of sustainable materials, such as biodegradable plastics or recycled components, to minimize waste and environmental impact.

- Energy Efficiency: Contract manufacturers are implementing energy-efficient technologies and processes to reduce energy consumption. This includes optimizing machinery, utilizing renewable energy sources, and improving overall energy management.

- Waste Reduction: Lean manufacturing principles are being adopted to minimize waste throughout the production process. Manufacturers are also focusing on recycling and reusing materials wherever possible.

Embracing sustainability not only helps companies meet regulatory requirements but also enhances brand reputation and appeal to environmentally conscious consumers, making it a vital consideration for future growth.

3. Regionalization of Supply Chains

In response to global disruptions and the need for more resilient supply chains, there is a noticeable shift toward regionalization. Companies are reevaluating their supply chains to reduce reliance on distant manufacturers and improve agility. This trend includes:

- Local Sourcing: Businesses are increasingly looking to source materials and production closer to their markets to mitigate risks associated with global supply chain disruptions, such as transportation delays or geopolitical tensions.

- Nearshoring: Many companies are moving production facilities closer to home, often to neighboring countries, to balance cost and efficiency while increasing control over the manufacturing process.

- Diversification of Suppliers: Companies are working with multiple suppliers across different regions to reduce risks associated with over-reliance on a single source, thereby enhancing supply chain resilience.

By regionalizing supply chains, businesses can respond more swiftly to market changes, reduce lead times, and improve customer service, all while maintaining cost-effectiveness.

Choosing the right contract manufacturer

The risks that come with working with a contracted third-party provider can be avoided by carefully vetting potential partners. When conducting due diligence on prospective partners, it’s important to consider the following factors.

What Equipment and Technologies Do They Have?

Assessing the facilities, machines, and equipment the manufacturing partner has available to them is key to choosing the right fit. A company looking for a contract manufacturer should be knowledgeable about current production techniques and technology, as these directly translate to costs and the quality of finished goods. They should also ask the manufacturer about the equipment available and make sure it can accommodate the materials that need to be used for fabrication.

Can They Grow with Your Business?

A company should select a manufacturer that can grow alongside its business and be able to scale operations to meet its needs. Demand can fluctuate, and a manufacturing partner needs to be able to match spikes in demand so revenue isn’t left on the table.

It’s also important to consider if the manufacturer is able to expand operations to match needs for new components and products, otherwise, a business may find itself looking to a growing list of additional suppliers, increasing order complexity.

Are they reputable?

This might seem obvious, but a company should seek to partner with a manufacturer that has established itself as trustworthy in the industry. Not only are these companies more likely to produce desirable output, but they also have a vested interest in protecting their reputation (so they are more likely to quickly resolve any problems that arise). Before partnering, a company should look for positive reviews on places like the Better Business Bureau and Google, and review examples of past projects the manufacturer has done (asking for examples that are similar to the project, if possible).

Finally, it pays to do a bit more research and look on the provider’s website for information about the team. A company should inquire about relevant staff experience and completed projects to help ensure a good fit and reduce risk.

Review their Certifications

Conduct a Feasibility Study

When evaluating contract manufacturers, a company should assess how a partner will fit within their business model. Conducting a feasibility study for outsourcing fabrication will include collecting data about the project, mapping out comparative costs of producing the product in-house (including overhead costs, labor, equipment purchases and maintenance, depreciation, quality assurance, and other aspects of production), reviewing differences in production time and the impact this difference will have in meeting demand, etc.

Consider all costs

Some costs associated with outsourced manufacturing are not as obvious. Such as shipping costs, tariffs, compliance requirements, and packaging. A company needs to be aware of all potential costs of outsourced vs in-house production.

Are they a strong communicator?

Working with a partner requires frequent discussions between the two parties, so communication is vital to success. Early discussions with a prospective third-party supplier can help signal how effectively they communicate. Do they proactively communicate and make an effort to keep all parties informed on progress and potential challenges? Working with a partner that provides great communication is essential to ensure that the manufacturing process of your products is going smoothly. This becomes even more important when the manufacturer is overseas, making visiting and checking operations more difficult.

where are they located?

Where a contract manufacturer is located can be important to their viability as a production partner. Farther distance means higher shipping costs.—. A nearby facility may also make it easier for meetings (both in-person and remote meetings due to fewer time zone shifts).

When To Consider A Contract Manufacturing Partner

Contract manufacturing isn’t the best manufacturing option in every scenario. Some companies are much better off keeping production in-house than utilizing manufacturing partners. Typically, these situations may warrant considering a third-party partner:

You Need Products Quickly: By working with an experienced manufacturer, you cut out a large part of the trial and error process when attempting to manufacture a product. Allowing you to decrease time-to-market.

You Have Fluctuating Demand: If your company experiences things like seasonal demand, it could be beneficial to work with a contract manufacturer for those high-demand times.

You Need to Conserve Capital: By working with a contract manufacturer, the costs allocated towards manufacturing products are significantly lower than if you ran operations in-house. Allowing for less capital outlay.

Take Care Of Your Contract Manufacturing Needs With Nautical

For any manufacturing needs, our direct relationships with sourcing specialists internationally allow us to provide high-quality products in the most cost-effective way for our customers. The value doesn’t just end there though, we are committed to quality. That is why we have on-site quality inspections of all products to ensure they are up to standards every time.

In addition to all our manufacturing services, we also offer 3PL, freight, contract packaging and repacking, and many other value-added services to clients allowing us to be a full-service supply chain partner for any company’s needs.